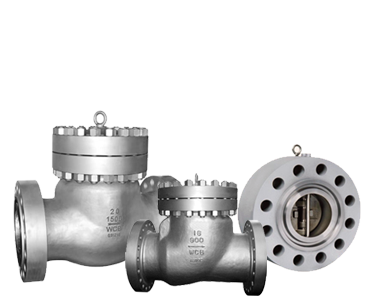

I.Exquisite Structural Design

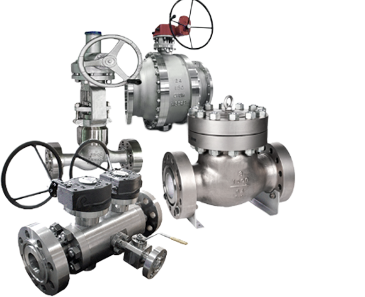

The structure of the check valve is not complicated, but every component is crucial. The core component is the valve disc, which is usually round or conical, installed inside the valve body and can be freely moved. The valve body is the "shell" of the entire valve that holds the fluid and provides support for other components. The valve seat is located inside the valve body and is closely matched with the valve disc to form a sealing surface. When the fluid is flowing forward, the disc is separated from the seat. When the fluid tries to flow back, the disc snaps against the seat, preventing the fluid from passing through. In addition, some check valves are equipped with a rocker or spring device to enhance disc sensitivity and seal performance.

II.Unique Working Principle

The working principle of the check valve is based on the pressure difference of the fluid and the automatic action of the valve disc. When the fluid enters through the inlet end, its pressure pushes the disc away from the seat, opening the valve channel and allowing the fluid to pass through. When the fluid tries to flow in the opposite direction, the pressure acts on the other side of the disc, causing it to quickly fit the seat and close the channel, thus preventing the fluid from flowing back. This process is completely automatic and requires no human intervention, ensuring a one-way flow of fluid.

III.Wide Range Of Application Scenarios

With its simple and efficient structure and working principle, check valves are widely used in various industrial and civil fields. In the water supply and drainage system, it can effectively prevent the backflow of water when the pump stops, and protect the pump and pipeline from damage; In the field of petrochemical industry, it can prevent corrosive media backflow, avoid equipment corrosion and leakage; In the HVAC system, it ensures the one-way flow of hot and cold water to maintain the stable operation of the system. It can be said that check valves are an integral part of modern fluid control systems.