| Availability: | |

|---|---|

| Quantity: | |

Q41F

J-VALVES

BV17

Basic Information

Name: 2PC Cast Steel Flange Floating Ball Valve

Manufacturer:ZHEJIANG J-VALVES FLUID EQUIPMENT CO., LTD

Design Features

Precision casting process

Blow - Out Proof Stem design

Equipped with anti - static device

With locking handle

Has ISO 5211 direct mounting interface

Complies with API607 fire - proof standard

Specifications

Size: 1/2" - 10"

Design Standard: API608/API6D

Flange Standard: ASME B16.5

Face - to - Face Dimension: ASME B16.10

Testing Standard: API598

Materials

Body: WCB/CF8/CF8M

Ball: SS304/SS316

Stem: SS304/SS316

Seat: PTFE/RPTFE/PPL

Other special materials such as Duplex stainless steel, Super duplex stainless steel ,bronze, titanium alloy, Inconel, Monel, etc. can also be used for manufacturing.

Operating Conditions

Working Temperature (W.T): -27~150~220°C~280°C

Working Pressure (W.P): 150Lb - 300Lb~600Lb

Technical drawings

DRAWING FLOATING BALL VALVES.pdf

DRAWING FLOATING BALL VALVES.pdf

Why Choose Our Floating Ball Valves?

1.Reliable seat seal floating ball valves

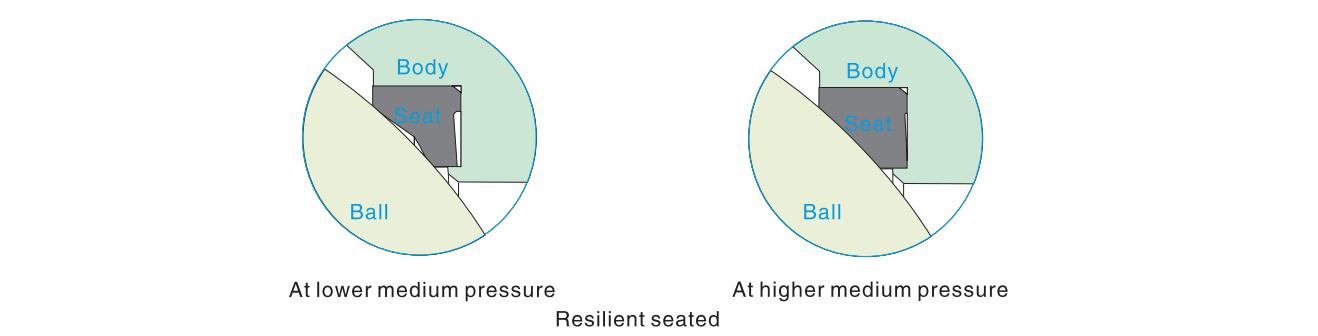

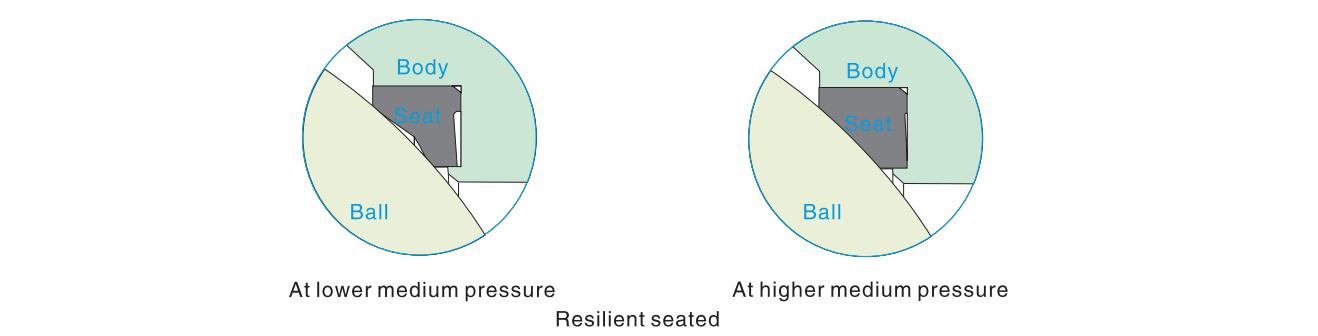

The structure design of elastic sealing ring has beeen adopted for floating ball valves. This seat design features a bigger sealing pressure ratio between thering surface and the ball when medium pressure gets lower, where the contacting area is smaller. Thus, the reliable seal is ensured. When the medium pressure gets higher, the contacting area between seat ring and ball becomes bigger as the Ball sealing ring transforms elastically to undertake the bigger force pushed by the medium without any damage.

2.Fire safe design floating ball valves

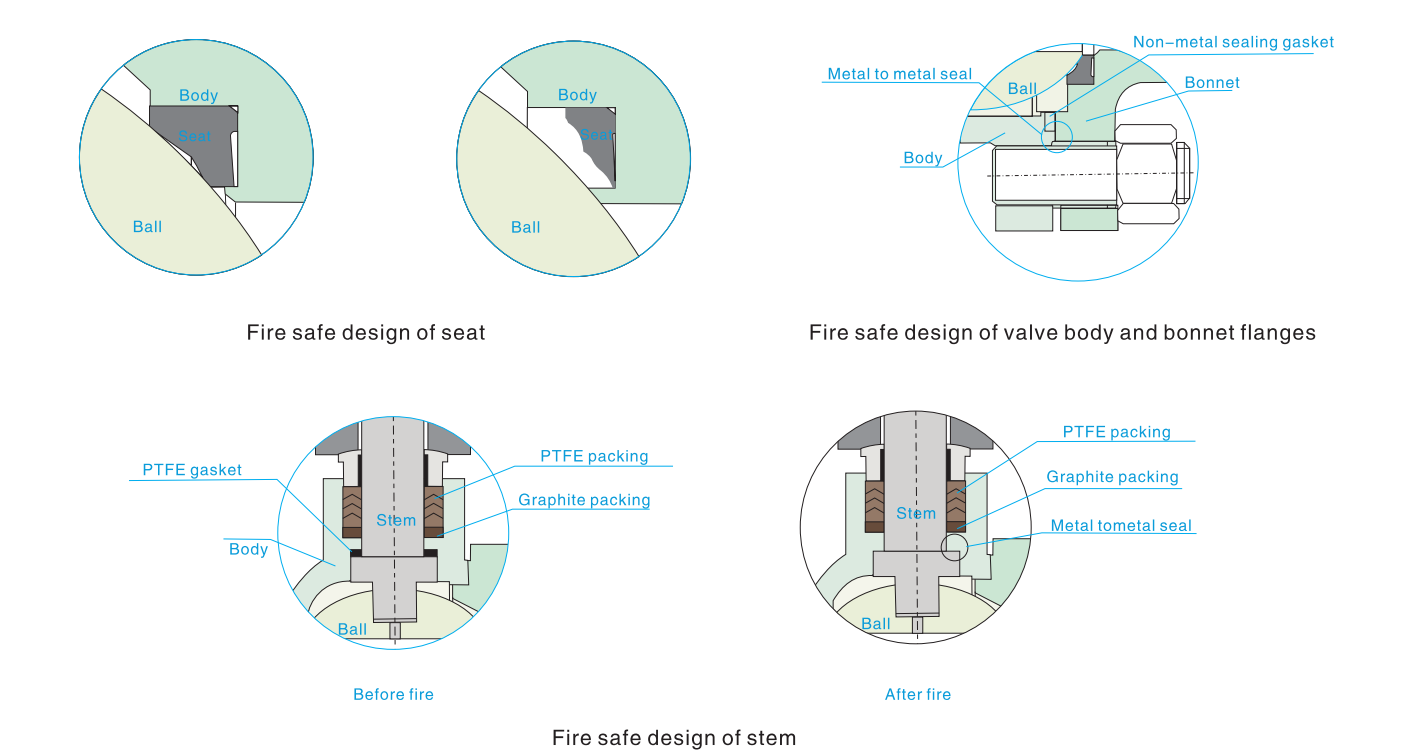

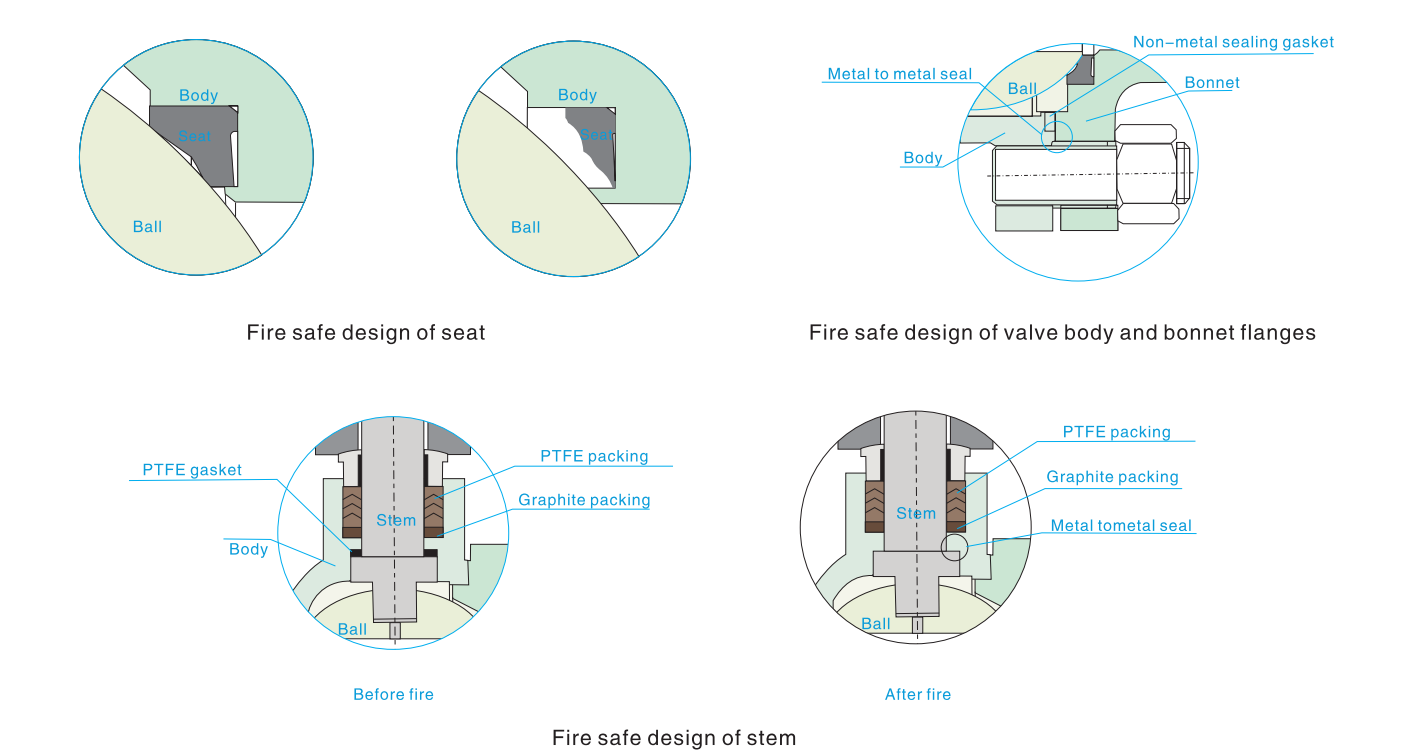

With the valve heated in a fire application, the non--metal material parts such as seat sealing ring of PTFE, stem back seat gasket, gland packing, and ithe sealing gasket between body and bonnet might disintegrate or be damaged due to high temperature.J-VALVES's specially designed structure of auxiliary metal to metal seal is provided to effectively preventboth internal and external Ball leakage of the valve. As required by customers, J-VALVES's floating ball vallves with fire safe design can meet the requirement of API607,API 6FA,BS 6755 and JB/T 6899.

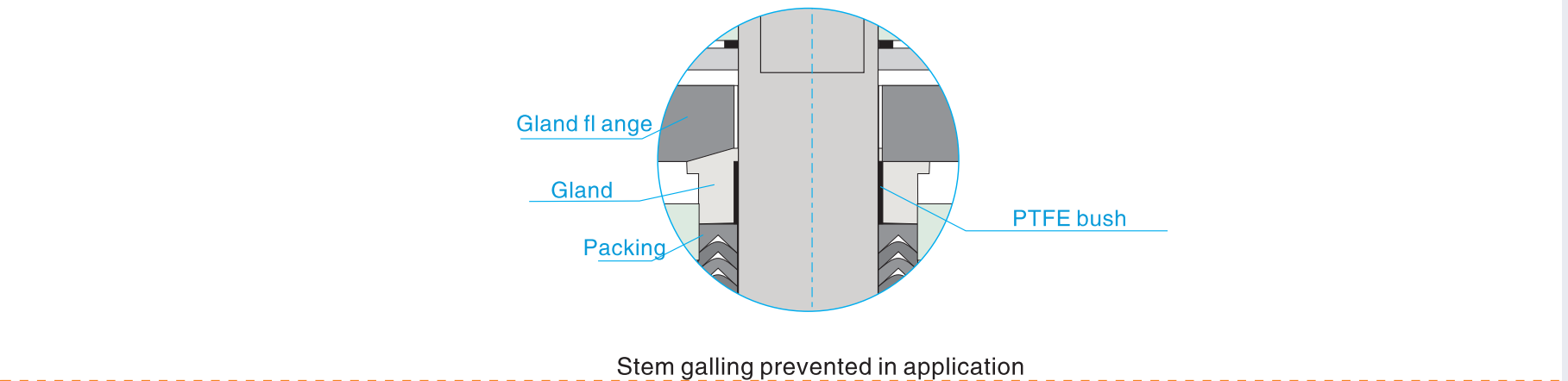

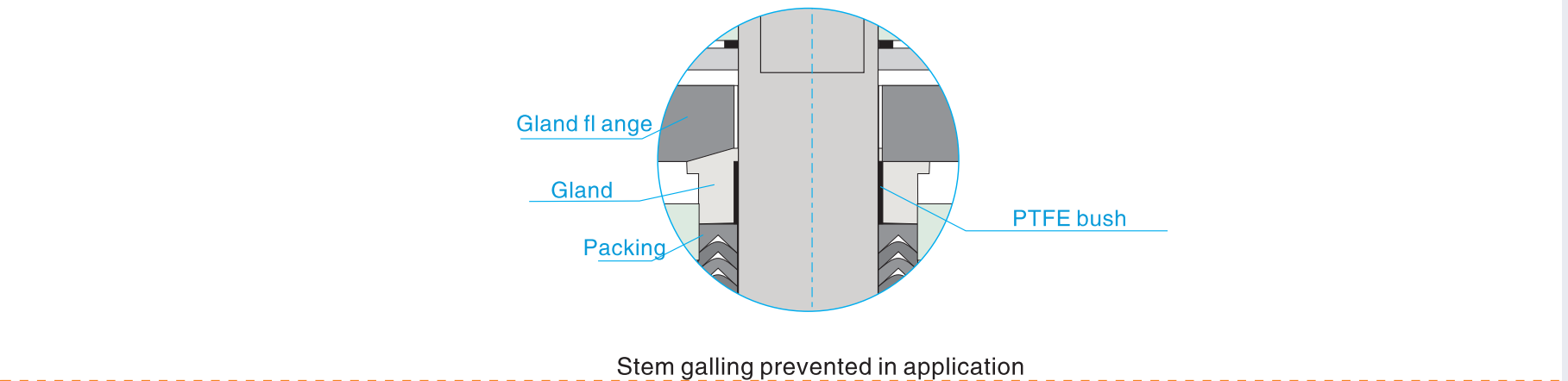

3.Reliable stem seal floating ball valves

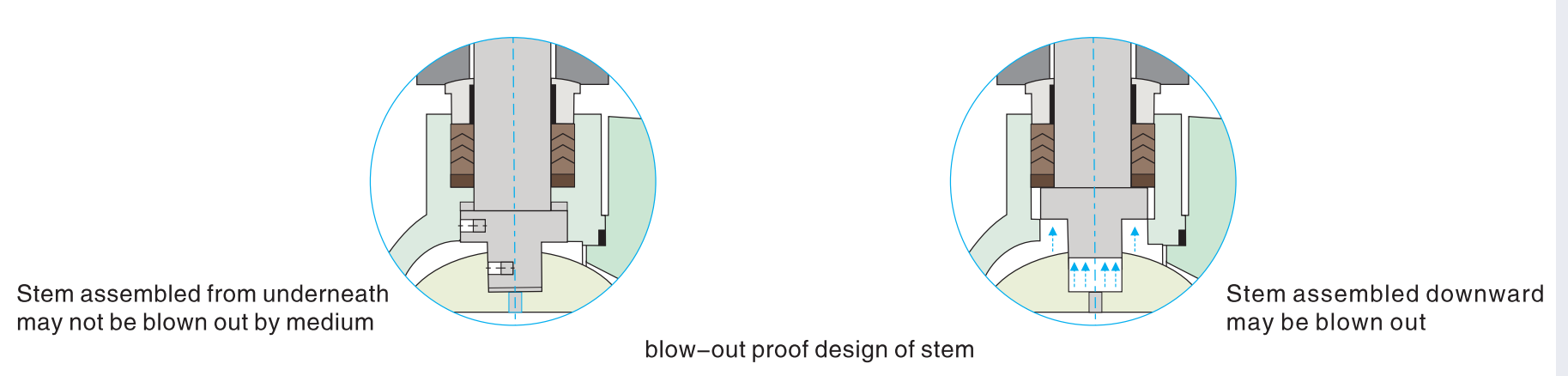

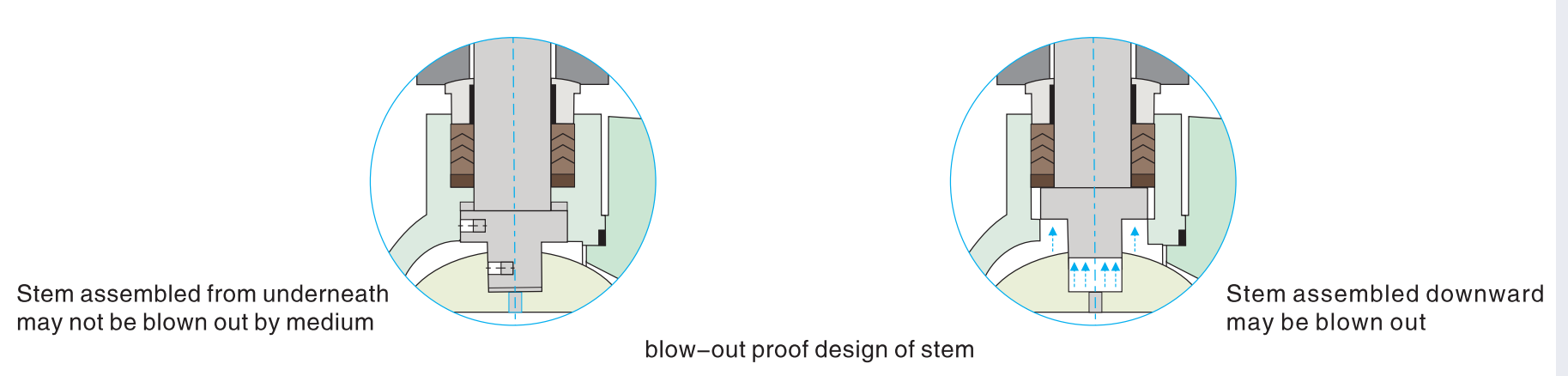

The blow-out proof design has been adopted forthe stem to ensure that even if the pressure in the body cavity is risen accidently and the packing flange becomes invalid, the stem may,not be blown out by medium. The stem features the design with a back seat, being assembled from underneath. The sealing force against the backseat gets higher as the medium pressure becomes higher. So the reliable seal of the stem can be assured under variable medium pressure.

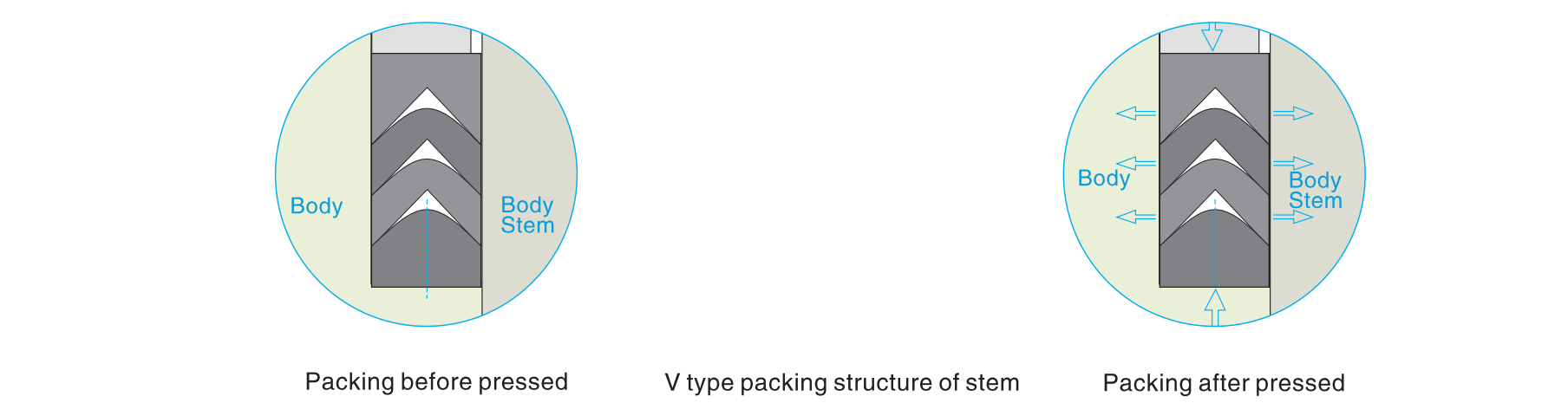

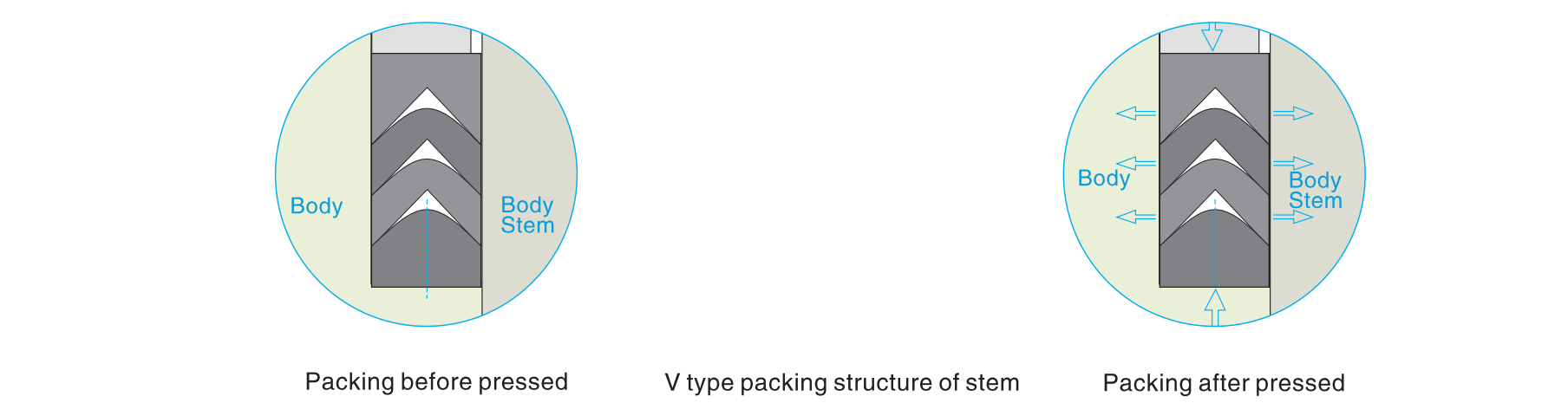

V type packing structure has been employed to efffectively transform the pushing force of the gland flange and the medium pressure into the sealing force against the stem.

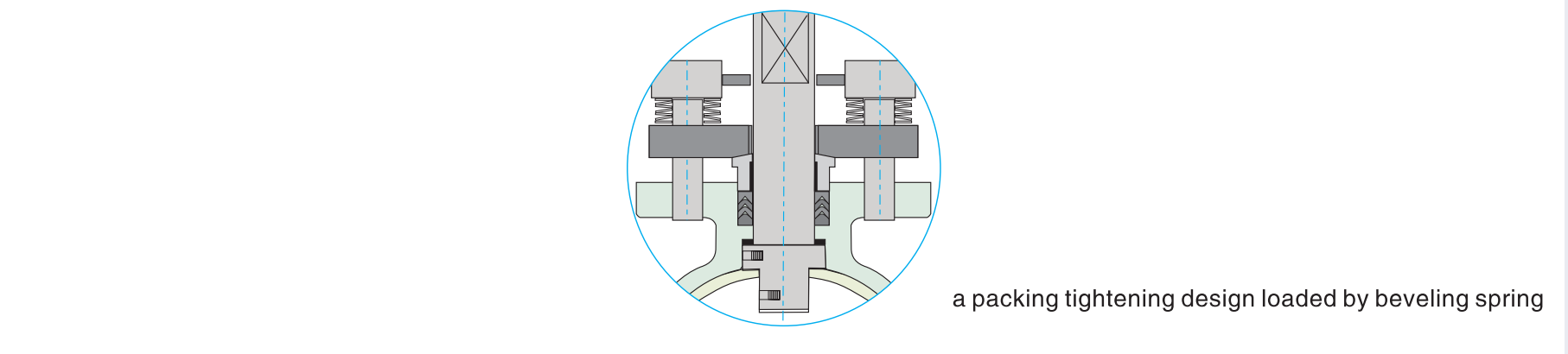

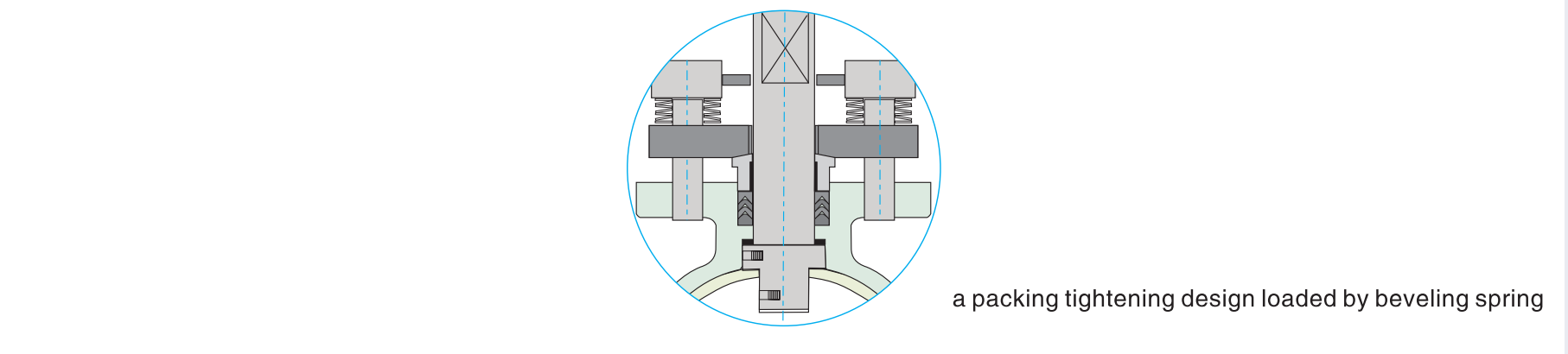

Based on customers' requirement, a packing tightening design may be employed to obtain more reliable stem packing seal, which is loaded by beveling spring.

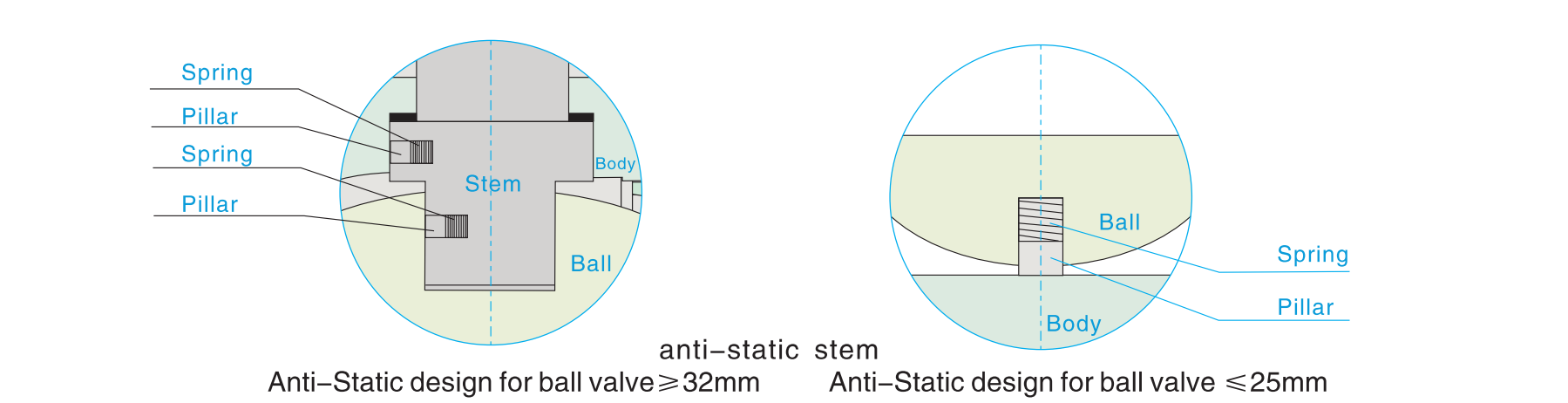

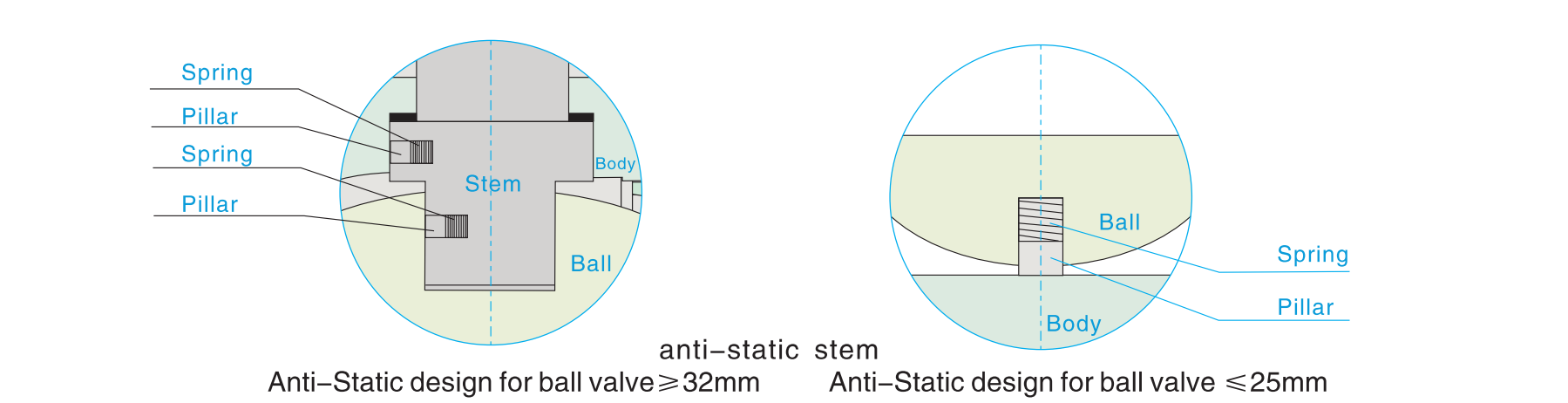

4.Anti-staticfeature floating ball valves

The traditional packing flange design has been imoroved to be of two piece structure, i.e., being as a packing flange plate and a follower, the latter contacts the flange plate with spherical surface. Thus, the follower remains vertical always, and is lined internallywith a PTFE bush to prevent the galling against and friction between the stem, which can also reduce the operation torque of the valve.

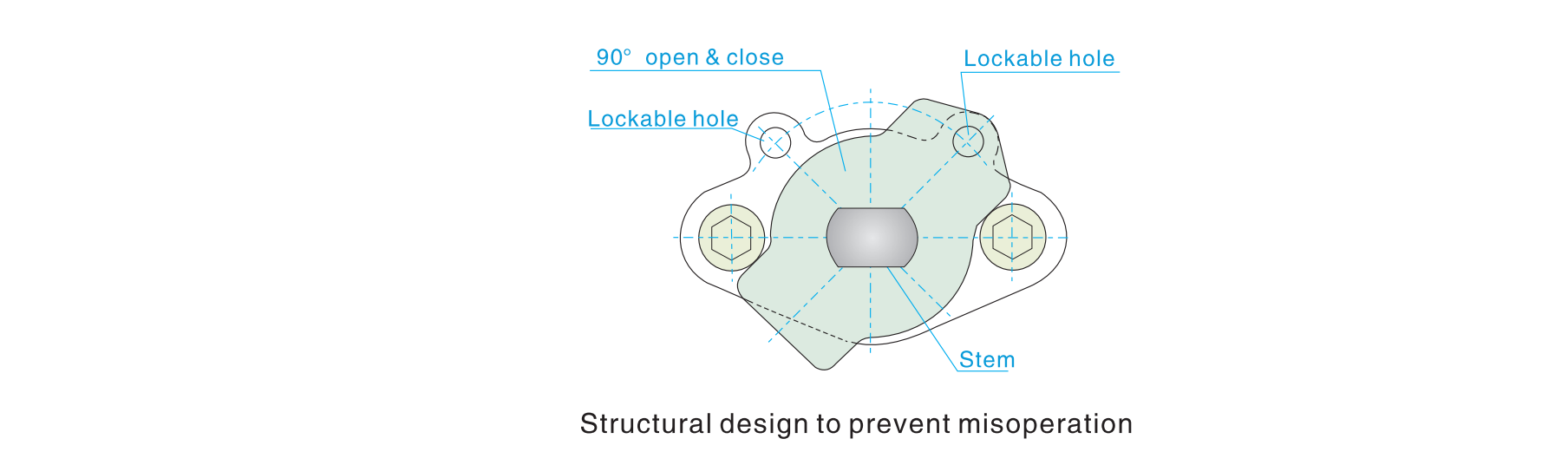

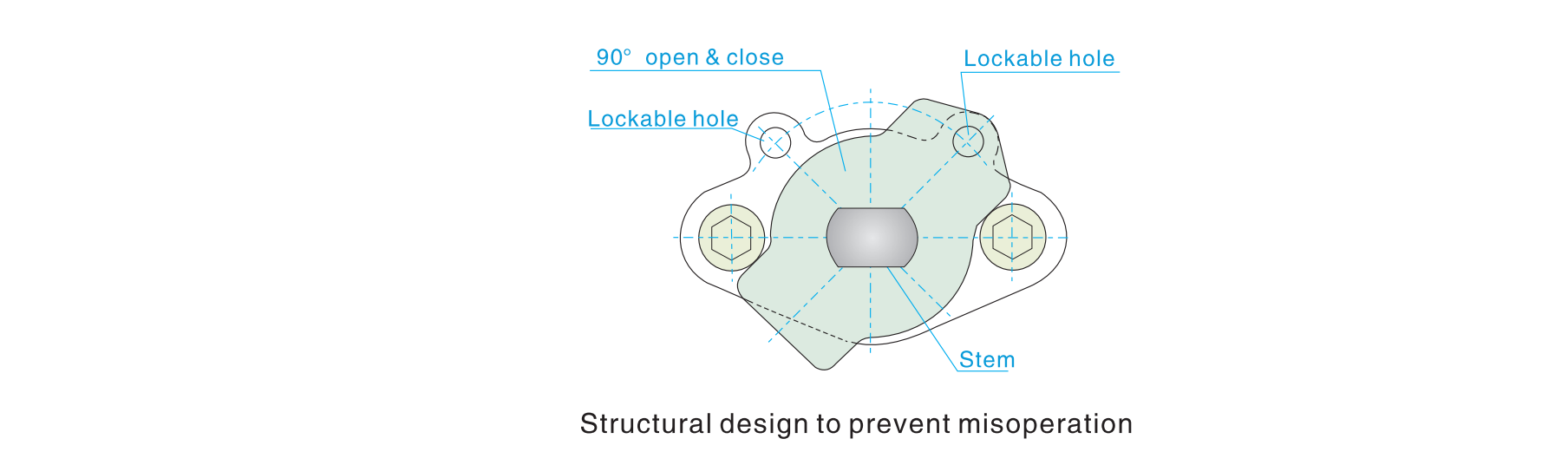

5.Gear operation prevention

To prevent the ball valve from gear operation, the key lock with 90 of open and close positioning pad has been provided, which can be lockable as required. At the stem head, where the lever fixes, a flat is so designed fhat the valve opens with the lever in parallelto piping, and with the lever right-angled to the piping, the valve is closed. So, it is ensured that the valve indicator of open and close can never make mistake.

Basic Information

Name: 2PC Cast Steel Flange Floating Ball Valve

Manufacturer:ZHEJIANG J-VALVES FLUID EQUIPMENT CO., LTD

Design Features

Precision casting process

Blow - Out Proof Stem design

Equipped with anti - static device

With locking handle

Has ISO 5211 direct mounting interface

Complies with API607 fire - proof standard

Specifications

Size: 1/2" - 10"

Design Standard: API608/API6D

Flange Standard: ASME B16.5

Face - to - Face Dimension: ASME B16.10

Testing Standard: API598

Materials

Body: WCB/CF8/CF8M

Ball: SS304/SS316

Stem: SS304/SS316

Seat: PTFE/RPTFE/PPL

Other special materials such as Duplex stainless steel, Super duplex stainless steel ,bronze, titanium alloy, Inconel, Monel, etc. can also be used for manufacturing.

Operating Conditions

Working Temperature (W.T): -27~150~220°C~280°C

Working Pressure (W.P): 150Lb - 300Lb~600Lb

Technical drawings

DRAWING FLOATING BALL VALVES.pdf

DRAWING FLOATING BALL VALVES.pdf

Why Choose Our Floating Ball Valves?

1.Reliable seat seal floating ball valves

The structure design of elastic sealing ring has beeen adopted for floating ball valves. This seat design features a bigger sealing pressure ratio between thering surface and the ball when medium pressure gets lower, where the contacting area is smaller. Thus, the reliable seal is ensured. When the medium pressure gets higher, the contacting area between seat ring and ball becomes bigger as the Ball sealing ring transforms elastically to undertake the bigger force pushed by the medium without any damage.

2.Fire safe design floating ball valves

With the valve heated in a fire application, the non--metal material parts such as seat sealing ring of PTFE, stem back seat gasket, gland packing, and ithe sealing gasket between body and bonnet might disintegrate or be damaged due to high temperature.J-VALVES's specially designed structure of auxiliary metal to metal seal is provided to effectively preventboth internal and external Ball leakage of the valve. As required by customers, J-VALVES's floating ball vallves with fire safe design can meet the requirement of API607,API 6FA,BS 6755 and JB/T 6899.

3.Reliable stem seal floating ball valves

The blow-out proof design has been adopted forthe stem to ensure that even if the pressure in the body cavity is risen accidently and the packing flange becomes invalid, the stem may,not be blown out by medium. The stem features the design with a back seat, being assembled from underneath. The sealing force against the backseat gets higher as the medium pressure becomes higher. So the reliable seal of the stem can be assured under variable medium pressure.

V type packing structure has been employed to efffectively transform the pushing force of the gland flange and the medium pressure into the sealing force against the stem.

Based on customers' requirement, a packing tightening design may be employed to obtain more reliable stem packing seal, which is loaded by beveling spring.

4.Anti-staticfeature floating ball valves

The traditional packing flange design has been imoroved to be of two piece structure, i.e., being as a packing flange plate and a follower, the latter contacts the flange plate with spherical surface. Thus, the follower remains vertical always, and is lined internallywith a PTFE bush to prevent the galling against and friction between the stem, which can also reduce the operation torque of the valve.

5.Gear operation prevention

To prevent the ball valve from gear operation, the key lock with 90 of open and close positioning pad has been provided, which can be lockable as required. At the stem head, where the lever fixes, a flat is so designed fhat the valve opens with the lever in parallelto piping, and with the lever right-angled to the piping, the valve is closed. So, it is ensured that the valve indicator of open and close can never make mistake.

What Makes C95800 Bronze So Special?C95800, also known as aluminum bronze, is a high-performance alloy renowned for its exceptional mechanical properties:Unmatched Wear Resistance: The alloy's unique composition—rich in copper, aluminum, iron, and nickel—creates a dense, hard surface that resists sc

1. Understanding Pressure Ratings (PN16 to PN100)The pressure rating of a floating flange ball valve is expressed in PN, where PN16 indicates a valve rated for 16 bar (or approximately 232 psi) and PN100 indicates a valve rated for 100 bar (or approximately 1450 psi). These ratings are determined by

Understanding Y-Type and Basket StrainersY-Type StrainersStructure and FunctionY-type strainers consist of a cylindrical body, a Y-shaped strainer basket, and connections for inlet and outlet pipes. The strainer basket, typically made of perforated metal or mesh, allows fluid to pass through while t

Project Case Study: Reliable Solid Particle Protection for Industrial PipelinesProject BackgroundIn recent years, wastewater treatment and reuse projects in Kazakhstan have continued to expand, especially in municipal infrastructure, mining support systems, and industrial process water applications.

In modern industrial fluid control systems, material selection often determines the service life and safety of the system. The ASTM B62 Bronze Gate Valve has become a core component in marine engineering, heating, ventilation, and air conditioning (HVAC) as well as water supply and drainage systems,

In the realm of industrial fluid handling, stainless steel Y-type strainers stand as a cornerstone of system reliability, efficiency, and longevity. Engineered to remove debris, particles, and contaminants from pipelines, these devices play a pivotal role in safeguarding equipment, reducing downtime

Structure and Working Principle of Double Disc Bronze Check ValveThe double disc bronze check valve is mainly composed of a valve body, two half-disc valve discs, a hinge mechanism, and sealing surfaces. The discs are connected by hinges and installed inside the valve body, enabling them to automati

In industrial fluid systems, filters are critical components that ensure system cleanliness and prevent contaminants from entering. The J-VALVES 2" 600LB CF8M Y-Type Filter is a high-efficiency, reliable filtration solution suitable for a wide range of industrial applications.1. High Pressure Resist

In industrial production, high temperature working conditions impose extremely stringent requirements on the performance of equipment. Especially in the filtration process involving high-temperature fluids, it is crucial to choose the appropriate filter material and model. Y-type strainer made of nickel aluminum bronze B148 (C95800) material have become the first choice for many engineers due to their excellent high temperature resistance and corrosion resistance.

What is a B62 Bronze Gate Valve?The B62 Bronze Gate Valve is a type of gate valve designed for industrial use, primarily in fluid control systems. Constructed from Ni-Al bronze, it offers excellent resistance to corrosion, high temperature, and pressure, making it an ideal choice for demanding envir

In the field of shipbuilding, seawater filtration is an important link to ensure the normal operation of key systems of ships. As a high-performance seawater filtration device, the C95800 strainer has become an indispensable component in shipbuilding due to its outstanding corrosion resistance, high

What Are Gate Valves?A gate valve is a type of valve that uses a sliding gate to control the flow of fluid. The gate moves vertically within the valve body to open or close the passage. When fully open, the gate valve creates a straight path for the flow of fluids, allowing minimal pressure drop. Ga

In modern industrial fluid control systems, tiny impurities are often the "invisible killers" that cause costly equipment failures. Founded in 2009, J-VALVES has been committed to the R&D and manufacturing of industrial valve solutions. Among our products, the Y-Strainer has become a core component for protecting pumps, compressors, and instrumentation systems due to its exceptional filtration efficiency and durability.

Understanding J-VALVES High-Performance Gate ValvesJ-VALVES' high-performance gate valves are designed with advanced engineering principles to ensure they can withstand the rigors of industrial use. These valves are available in a variety of sizes, materials, and configurations, allowing them to be

Selection Guide(1) Selection Based on Fluid CharacteristicsLiquid: If the fluid is water or a low-viscosity liquid with few impurities, a Y-type strainer can be selected; if the fluid is oil or contains a large amount of impurities, it is recommended to choose a basket strainer.Gas: For gas filtrati

In process systems such as petrochemical, industrial water treatment, energy, power, and fine chemical industries, pipeline clogging due to impurities remains one of the core issues affecting stable system operation. Once welding slag, rust, sand particles, or solid debris enter the pipeline, they not only cause valve jamming and pump wear but may also lead to unplanned shutdowns, resulting in high maintenance costs.

In the world of industrial processing, pipeline integrity is paramount. Any contamination within pipelines can result in costly damage to machinery, reduced efficiency, and potential downtime. This is where Basket and Y-type strainers come into play, serving as critical filtration devices for a vari

Y-type strainerStructural DesignThe Y-type strainer is shaped like the letter "Y". It is mainly composed of nozzles, the main pipe, a strainer screen, flanges and fasteners. The strainer screen is installed inside the main pipe. After the fluid enters from the inlet, it is strainered through the str

In industrial pipeline systems, protecting critical equipment from solid contaminants is essential for long-term reliability and operational safety. This is where the J-VALVES basket strainer plays a vital role. Designed for high flow capacity and efficient particle removal, it is widely used across industries where fluid cleanliness directly impacts system performance.

Understanding Double Block-and-Bleed (DBB) Ball ValvesDBB ball valves are designed to provide two independent seals (one upstream and one downstream) and a bleed port to vent any trapped fluid between the seals. This design ensures that the valve can safely isolate a section of the pipeline and reli