| Availability: | |

|---|---|

| Quantity: | |

J-VALVES-GV-1550

J-VALVES

8481804090

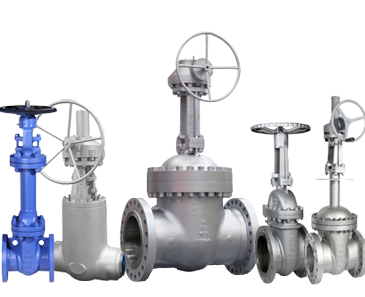

In the crucial realm of industrial fluid control, the China-Made J-VALVES 150LB DN50 Flange End RF Duplex Stainless Steel CF8m Gate Valve, equipped with a bevel gear operation mechanism, emerges as a game-changer, bringing outstanding performance and excellent craftsmanship to power global industrial scenarios.

Product Name | 150LB DN50 Flange End RF Duplex Stainless Steel CF8m Gate Valve |

Material | WCB/CF8/CF8M/LCC/LCB/WC6/WC9 |

Pressure | 150LB/300LB/600LB/900LB/1500LB/2500LB |

Size | 2 inch~ 60 inch(DN50~DN1500) |

End Connection | RF/RTJ/BW/SW |

Working Temp | -196ºC~400ºC. |

Mode of operation | Handwheel (2"~12") & Bevel Gear (14"&above) |

Suitable Medium | Water,Natural Gas,Oil and some corrosive liquid |

Features | Rising stem,OS&Y,Bolted Bonnet or Pressure Sealed,non-rising stem option |

Exceptional Material Composition:Constructed from duplex stainless steel CF8m, this gate valve benefits from the unique blend of austenitic and ferritic structures. This alloy offers outstanding corrosion resistance, high mechanical strength, and robust protection against pitting and crevice corrosion. It can endure harsh chemical environments, making it suitable for applications involving aggressive fluids, thus reducing maintenance and replacement costs.

Reliable Flange End Connection:The raised face (RF) flange end design ensures a secure and leak - tight connection to the pipeline. The RF surface, with its slightly elevated sealing area, creates a better seal when mated with a corresponding flange. This connection method simplifies installation and maintenance, as flanges can be easily bolted together. It also withstands the forces exerted by fluid flow, ensuring system integrity.

Efficient Flow Control:As a gate valve, it provides precise flow control. The gate can be fully opened for unrestricted flow or gradually closed to regulate the flow rate accurately. This is crucial for applications where exact fluid control is necessary, such as chemical reactions where reactant quantities need careful management, enhancing production efficiency and product quality.

Fire - Resistant Design (Optional):For applications in high - risk environments, an optional fire - resistant design is available. When exposed to fire, special components and seals maintain the valve's integrity, preventing the spread of flames and leakage of hazardous fluids, ensuring safety in critical situations.

Anti - Static Functionality:In applications handling flammable or explosive media, the valve is equipped with an anti - static mechanism. This discharges static electricity generated during valve operation, preventing the ignition of flammable substances, and enhancing safety in industries like oil and gas, and petrochemicals.

Installation: The valve is designed for easy installation. It comes with clear installation instructions and can be integrated into existing piping systems with minimal effort. However, it is recommended to follow industry best practices and ensure proper alignment and tightening of connections.

Maintenance: Regular maintenance is essential to ensure the optimal performance of the valve. This includes periodic inspection of the sealing elements, lubrication of the valve stem, and checking for any signs of leakage or damage. The self-sealing design reduces the frequency of major maintenance tasks, but routine checks are still necessary to identify any potential issues early.

Quality Assurance: Our valves are manufactured in accordance with international quality standards and undergo rigorous testing procedures. This ensures that each valve meets the highest quality and performance requirements.

Technical Support: We provide comprehensive technical support to our customers. Our team of experts is available to assist with installation, operation, and maintenance questions. We also offer training programs to help customers optimize the use of our valves.

Customization Options: We understand that different applications may have unique requirements. Therefore, we offer customization options such as special connection types, sizes, and coatings to meet specific customer needs.

In the crucial realm of industrial fluid control, the China-Made J-VALVES 150LB DN50 Flange End RF Duplex Stainless Steel CF8m Gate Valve, equipped with a bevel gear operation mechanism, emerges as a game-changer, bringing outstanding performance and excellent craftsmanship to power global industrial scenarios.

Product Name | 150LB DN50 Flange End RF Duplex Stainless Steel CF8m Gate Valve |

Material | WCB/CF8/CF8M/LCC/LCB/WC6/WC9 |

Pressure | 150LB/300LB/600LB/900LB/1500LB/2500LB |

Size | 2 inch~ 60 inch(DN50~DN1500) |

End Connection | RF/RTJ/BW/SW |

Working Temp | -196ºC~400ºC. |

Mode of operation | Handwheel (2"~12") & Bevel Gear (14"&above) |

Suitable Medium | Water,Natural Gas,Oil and some corrosive liquid |

Features | Rising stem,OS&Y,Bolted Bonnet or Pressure Sealed,non-rising stem option |

Exceptional Material Composition:Constructed from duplex stainless steel CF8m, this gate valve benefits from the unique blend of austenitic and ferritic structures. This alloy offers outstanding corrosion resistance, high mechanical strength, and robust protection against pitting and crevice corrosion. It can endure harsh chemical environments, making it suitable for applications involving aggressive fluids, thus reducing maintenance and replacement costs.

Reliable Flange End Connection:The raised face (RF) flange end design ensures a secure and leak - tight connection to the pipeline. The RF surface, with its slightly elevated sealing area, creates a better seal when mated with a corresponding flange. This connection method simplifies installation and maintenance, as flanges can be easily bolted together. It also withstands the forces exerted by fluid flow, ensuring system integrity.

Efficient Flow Control:As a gate valve, it provides precise flow control. The gate can be fully opened for unrestricted flow or gradually closed to regulate the flow rate accurately. This is crucial for applications where exact fluid control is necessary, such as chemical reactions where reactant quantities need careful management, enhancing production efficiency and product quality.

Fire - Resistant Design (Optional):For applications in high - risk environments, an optional fire - resistant design is available. When exposed to fire, special components and seals maintain the valve's integrity, preventing the spread of flames and leakage of hazardous fluids, ensuring safety in critical situations.

Anti - Static Functionality:In applications handling flammable or explosive media, the valve is equipped with an anti - static mechanism. This discharges static electricity generated during valve operation, preventing the ignition of flammable substances, and enhancing safety in industries like oil and gas, and petrochemicals.

Installation: The valve is designed for easy installation. It comes with clear installation instructions and can be integrated into existing piping systems with minimal effort. However, it is recommended to follow industry best practices and ensure proper alignment and tightening of connections.

Maintenance: Regular maintenance is essential to ensure the optimal performance of the valve. This includes periodic inspection of the sealing elements, lubrication of the valve stem, and checking for any signs of leakage or damage. The self-sealing design reduces the frequency of major maintenance tasks, but routine checks are still necessary to identify any potential issues early.

Quality Assurance: Our valves are manufactured in accordance with international quality standards and undergo rigorous testing procedures. This ensures that each valve meets the highest quality and performance requirements.

Technical Support: We provide comprehensive technical support to our customers. Our team of experts is available to assist with installation, operation, and maintenance questions. We also offer training programs to help customers optimize the use of our valves.

Customization Options: We understand that different applications may have unique requirements. Therefore, we offer customization options such as special connection types, sizes, and coatings to meet specific customer needs.

In the field of high-pressure fluid control, J-VALVES high-pressure sealed globe valves demonstrate numerous remarkable advantages thanks to their outstanding flow characteristics and regulation performance. In terms of flow characteristics, they have a strong adaptability to nonlinear flow characte

I. Flow Characteristics: Nonlinear Adaptation and Low Pressure Drop Design 1. Precise Adaptation of Nonlinear Flow CharacteristicsJ-VALVES high-pressure globe valves adopt a unique valve disc profile optimization technique. Through CFD simulation of fluid dynamic behavior, a nonlinear flow character

In industrial fluid systems, filters are key devices that ensure the purity of fluids and protect downstream equipment from impurity damage. The Y-type filter is widely used in multiple fields such as chemical engineering, petroleum, water treatment, and food processing due to its unique structural

In industrial fluid processing, filters are key components that ensure the purity of fluids and protect the normal operation of equipment. Bronze C95800, as a high-performance copper alloy material, is widely used in the manufacture of filters due to its excellent strength, corrosion resistance and

Application Characteristics in Production Facilities of Different Scales (1) Small-scale Production Facilities1.Flow Requirements: Small-scale production facilities usually have a relatively small flow rate and do not have high requirements for the filtration area of the filter.2.Impurity content: T

Applicability of under Different Working Conditions(1) Flow Requirements• Low Flow Systems: Y-type strainer have a compact structure and are suitable for fluid systems with low flow rates and less impurities. • High-flow systems: The T-type strainer has a large filtration area and is suitable for hi

I. Y-type strainerStructural DesignThe Y-type strainer is shaped like the letter "Y". It is mainly composed of nozzles, the main pipe, a strainer screen, flanges and fasteners. The strainer screen is installed inside the main pipe. After the fluid enters from the inlet, it is strainered through the

Selection Guide(1) Selection Based on Fluid CharacteristicsLiquid: If the fluid is water or a low-viscosity liquid with few impurities, a Y-type strainer can be selected; if the fluid is oil or contains a large amount of impurities, it is recommended to choose a basket strainer.Gas: For gas filtrati

In the process of industrial fluid treatment, the efficiency and continuity of filters are key factors in ensuring the stable operation of the production process. As an innovative filtering device, the duplex filter can achieve high-efficiency filtering results and continuous uninterrupted operation

In industries such as petrochemical, offshore engineering, and sewage treatment, ball valves often face the challenges of complex working conditions such as acid-base corrosion, electrochemical corrosion, and erosion corrosion. The corrosion of valves not only affects their sealing performance and s

Stainless steel trunnion ball valve is a high-performance ball valve. Its core component is a sphere with a through hole. The sphere is fixed in the valve body through trunnions and can rotate 90 degrees. This design not only ensures the compactness and stability of the valve, but also improves the

In the vast system of industrial production, the purity of fluids plays a decisive role in the smooth operation of production processes and the assurance of product quality. As a highly efficient and widely used filtration device, the Y-type filter occupies a pivotal position in the field of industr

The double filter is a highly efficient and continuously operating filtration device, widely used in fields such as chemical engineering, pharmaceuticals, food, and water treatment. Through its unique design and working principle, it has solved the problem that traditional single-drum filters need t

Floating ball valves are extremely widely used in industrial and civil fields. Their size range plays a crucial role in adapting to different pipeline systems and working conditions. In terms of nominal diameter, the nominal diameter of common floating ball valves generally ranges from DN15 to DN250

Collaborative cooperation modeSeries connection cooperationIn the chemical pipeline system, Y-type filters and T-type filters can be used in series. The Y-type filter first removes small-sized impurities, and then the T-type filter removes large-sized impurities, thus improving the filtration accura

I. Structural differences(1) Y-type strainerAppearance structure· The Y-type strainer is in the shape of "Y", usually containing a right-angled elbow, enabling the strainer to be installed vertically or horizontally in the pipeline.· Its internal structure is relatively simple, mainly composed of th

In large-diameter pipeline systems, butterfly valves, ball valves, and gate valves are common types of valves. To make a reasonable selection among them, various factors need to be comprehensively considered.The structure of a butterfly valve is simple. The butterfly disc is installed in the directi

As a key component in fluid control systems, the performance and reliability of gate valves are crucial to the safety and efficiency of industrial production. Precision forging technology is an important means to improve the quality of gate valve. This paper analyzes the key links of precision forgi

Key Points for Selecting High-Pressure Ball Valves Medium CharacteristicsCorrosiveness: There are many types of petrochemical media with large differences in corrosiveness. For highly corrosive media such as acidic gases and oil and gas containing hydrogen sulfide, materials with strong corrosion r

Application of Y-Type Filters in Fine Chemicals(1) Structural and Performance Characteristics Y-type filters are named for their shape resembling the letter "Y". They are mainly composed of connecting pipes, main pipes, filter screens, flanges and fasteners. Its filter screen is usually made of s