| Availability: | |

|---|---|

| Quantity: | |

2“-56”

J-VALVES

API6D Stainless Steel Mounting Trunnion Ball Valve

The J-VALVES API6D stainless steel mounting trunnion ball valve employ investment or shell cast bodies & tailpieces, all produced from ASTM grade materials that are properly heat treated and chemically finished. All wall thicknesses comply with ASME B16.34 as do bolting stress levels.

Industrial and Oil/Gas piping applications requiring the higher flow capacity and lower pressure drop of full port internal flow-ways, and those applications where ease of repairability is desired.

API608 stainless steel mounting trunnion ball valve, constructed, and tested according to API and ASME/ANSI Standards. Other international standards including BS and DIN are also available upon request.

1. API6D Stainless Steel Mounting Trunnion Ball Valve Technical specifications:

l 3-Piece Bolted Body, Full Port Construction

l Fully Compliant to ASME B16.34

l Fully Compliant to API 6D

l API 607 6th Edition Fire-Safe

l Submerged Packing System & Direct Mount Actuation

l Second Generation PTFE Seats Provide Higher Operating Temperatures

l Standard Electrically Grounded Ball & Stem

2. API6D Stainless Steel Mounting Trunnion Ball Valve Product Specification:

l Size: 2''-56''(DN50~DN1400)

l Pressure Rating: 150LB-2500LB/PN16~PN100/10K~60K)

l Material: A351 CF8M/CF8/CF3/CF3M, A216 WCB, A352 LCB/LCC,A105/C3/F2/F51/F53/F304/F304L/F316/C95800

l Suitable Temperature: -196ºC~450ºC( Different temperature choose different materials).

l Suitable Medium: Water, Steam, Oil and natural gas etc.

3.API6D Stainless Steel Mounting Trunnion Ball Valve Product Feature:

l Fixed ball, full bore or reduce bore.

l Mounting trunnion Ball valve

l Blow-out proof stem design.

l PTFE/RPTFE seat seal( Seat seal material could be decided by customer's request or according to valve's medium & temp. condition).

l Anti-static design and API 607 Fire Safe Design available

l Operation: Hand wheel, Worm wheel,Gear, Pneumatic actuator & Electric Actuator.

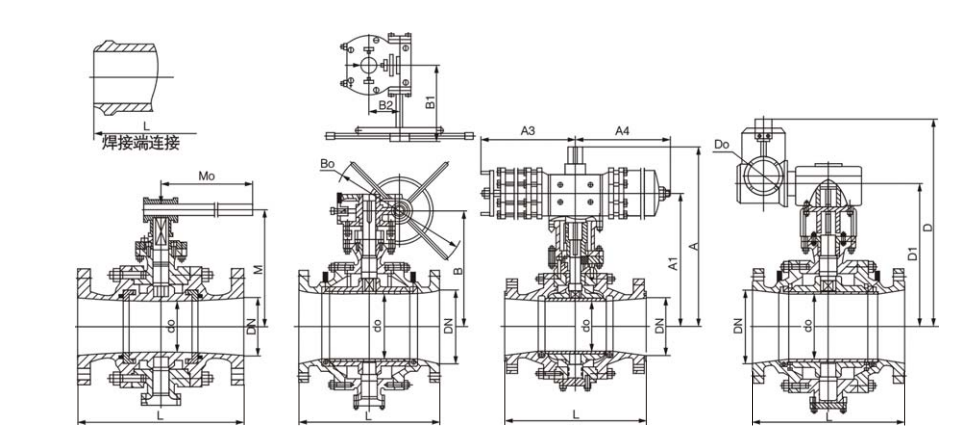

4. API6D Stainless Steel Mounting Trunnion Ball Valve Product Drawing:

5. API6D Stainless Steel Mounting Trunnion Ball Valve Low Operating Torque:

The trunnion pipeline ball valve adopts the trunnion ball structure and floating valve seat, so as to achieve lower torque under operating pressure. It uses self-lubricating PTFE and sliding bearing to reduce the friction coefficient to the lowest in conjunction with the high intensity and high fineness stem.

6. API6D Stainless Steel Mounting Trunnion Ball Valve Emergency Sealing Device:

The ball valves with the diameter more than or equal to 6″(DN150) are all designed with sealant injection device on stem and seat. When the seat ring or stem O ring is damaged due to accident, the corresponding sealant can be injected by the sealant injection device to avoid medium leakage on seat ring and stem. If necessary, the auxiliary sealing system can be used for washing and lubricating the seat to maintain its cleanliness.

Note: All the data should be confirmed with the approved drawings of manufacturer.

Tips:

We also manufacture other type valves, as butterfly valve, check valve, globe valve, Y strainer, sanitary butterfly valve, sanitary ball and so on.

Any item meets your interest, anything confused you, pls keep me posted, let's talk more.

J-VALVES Service:

l On Samples Buyer bear the air fee, but this fee will be reduced from order directly

l On After Sales Free replacement if there is any quality problem

l On Delivery Never delay delivery time

l On Materials Ensure material pure

l Ensure material pure

API6D Stainless Steel Mounting Trunnion Ball Valve

The J-VALVES API6D stainless steel mounting trunnion ball valve employ investment or shell cast bodies & tailpieces, all produced from ASTM grade materials that are properly heat treated and chemically finished. All wall thicknesses comply with ASME B16.34 as do bolting stress levels.

Industrial and Oil/Gas piping applications requiring the higher flow capacity and lower pressure drop of full port internal flow-ways, and those applications where ease of repairability is desired.

API608 stainless steel mounting trunnion ball valve, constructed, and tested according to API and ASME/ANSI Standards. Other international standards including BS and DIN are also available upon request.

1. API6D Stainless Steel Mounting Trunnion Ball Valve Technical specifications:

l 3-Piece Bolted Body, Full Port Construction

l Fully Compliant to ASME B16.34

l Fully Compliant to API 6D

l API 607 6th Edition Fire-Safe

l Submerged Packing System & Direct Mount Actuation

l Second Generation PTFE Seats Provide Higher Operating Temperatures

l Standard Electrically Grounded Ball & Stem

2. API6D Stainless Steel Mounting Trunnion Ball Valve Product Specification:

l Size: 2''-56''(DN50~DN1400)

l Pressure Rating: 150LB-2500LB/PN16~PN100/10K~60K)

l Material: A351 CF8M/CF8/CF3/CF3M, A216 WCB, A352 LCB/LCC,A105/C3/F2/F51/F53/F304/F304L/F316/C95800

l Suitable Temperature: -196ºC~450ºC( Different temperature choose different materials).

l Suitable Medium: Water, Steam, Oil and natural gas etc.

3.API6D Stainless Steel Mounting Trunnion Ball Valve Product Feature:

l Fixed ball, full bore or reduce bore.

l Mounting trunnion Ball valve

l Blow-out proof stem design.

l PTFE/RPTFE seat seal( Seat seal material could be decided by customer's request or according to valve's medium & temp. condition).

l Anti-static design and API 607 Fire Safe Design available

l Operation: Hand wheel, Worm wheel,Gear, Pneumatic actuator & Electric Actuator.

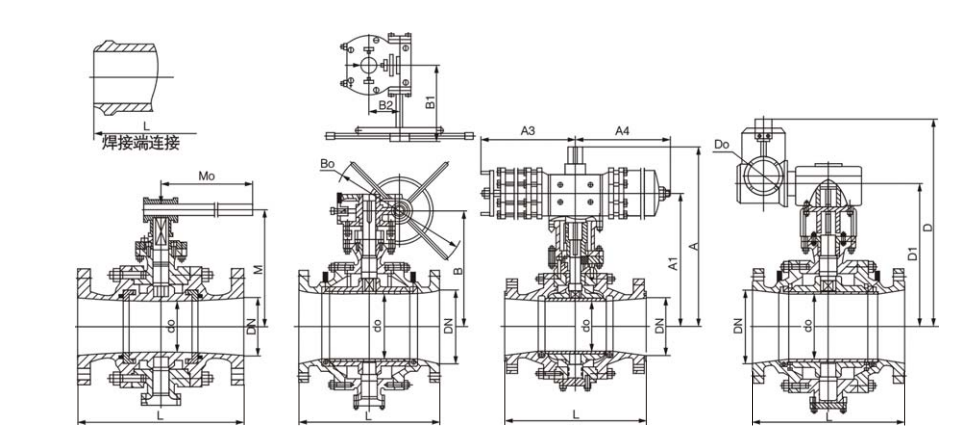

4. API6D Stainless Steel Mounting Trunnion Ball Valve Product Drawing:

5. API6D Stainless Steel Mounting Trunnion Ball Valve Low Operating Torque:

The trunnion pipeline ball valve adopts the trunnion ball structure and floating valve seat, so as to achieve lower torque under operating pressure. It uses self-lubricating PTFE and sliding bearing to reduce the friction coefficient to the lowest in conjunction with the high intensity and high fineness stem.

6. API6D Stainless Steel Mounting Trunnion Ball Valve Emergency Sealing Device:

The ball valves with the diameter more than or equal to 6″(DN150) are all designed with sealant injection device on stem and seat. When the seat ring or stem O ring is damaged due to accident, the corresponding sealant can be injected by the sealant injection device to avoid medium leakage on seat ring and stem. If necessary, the auxiliary sealing system can be used for washing and lubricating the seat to maintain its cleanliness.

Note: All the data should be confirmed with the approved drawings of manufacturer.

Tips:

We also manufacture other type valves, as butterfly valve, check valve, globe valve, Y strainer, sanitary butterfly valve, sanitary ball and so on.

Any item meets your interest, anything confused you, pls keep me posted, let's talk more.

J-VALVES Service:

l On Samples Buyer bear the air fee, but this fee will be reduced from order directly

l On After Sales Free replacement if there is any quality problem

l On Delivery Never delay delivery time

l On Materials Ensure material pure

l Ensure material pure

I. DESIGN FEATURES OF TRUNNION FLANGE BALL VALVES The design of TRUNNION FLANGE BALL VALVES is an important guarantee for their performance and reliability.According to the information I've searched, TRUNNION BALL VALVES usually adopt a three-piece or two-piece structure. Their characteristic is that the ball is fixed on the valve seat and will not shift when the valve is closed, thus ensuring stable and reliable sealing performance. In addition, they have a low operating torque and uniform sealing, making them suitable for high-pressure and large-diameter working conditions. For example, the Q476F type three-piece soft-seal flange ball valve of the J-VALVES brand is designed in accordance with API standards and has excellent sealing and pressure resistance.

I. IntroductionThe J-VALVES 15Mo3 gate valve is a high-performance fluid control device, which is widely used in industrial pipeline systems. This article will, from the perspective of comparative analysis, analyze its performance characteristics in detail and provide a comprehensive operating guide

1.PERFORMANCE COMPARISON: SOFT-SEAL PLUG VALVES: · SOFT-SEAL PLUG VALVES mainly rely on soft sealing materials to achieve sealing. They possess good sealing performance and low opening torque, and are suitable for pipeline systems carrying water, gas and non-corrosive media. · Their design features include low-torque operation, anti-static function and fireproof design, making them particularly suitable for occasions that require frequent opening and closing or high sealing requirements. · Under ultra-low or high temperature conditions, their torque requirements will increase, but they can still maintain stable performance through optimized design.

J-VALVES 2025 Labor Day Holiday NoticeDear Employees,As we approach the Labor Day holiday, we would like to express our highest respect and gratitude to all of you who have dedicated your efforts to J-VALVES. Your hard work is the driving force behind our success.Our Commitment: J-VALVES values each

API 600 vs BS 1873: Technical Differences and Selection ImpactWhen it comes to steel gate valves, API 600 and BS 1873 are two major international standards. Choosing the right standard for your application can significantly affect performance, safety, and cost. This article simplifies the comparison

I. API6D: Standard for Gate Valves in the Oil and Gas Industry(1) Overview of the API6D StandardAPI6D is a standard developed by the American Petroleum Institute (API) and is specifically used for pipeline valves in the oil and gas industry. This standard covers the design, manufacturing, testing, a

Applications of Gate Valves in Different Industries(1) Petrochemical IndustryThe petrochemical industry is one of the fields where gate valves are most widely applied. Gate valves play a crucial role in oil and gas exploration and transportation, as well as in refining and chemical production.Oil an

I. Overview of High-pressure Gate ValvesA high-pressure gate valve is a type of valve used to control the flow of high-pressure fluids, and it is widely applied in industries such as petroleum, natural gas, chemical engineering, and power generation. Its main function is to open or close the fluid p

I. Overview of API 600 and BS 1873 Standards(I) API 600API 600 is a standard developed by the American Petroleum Institute (API) and is applicable to steel gate valves in the petroleum and natural gas industries. These valves are primarily designed for high-pressure and high-temperature environments

In Russia's industrial landscape, valves play a crucial role in fluid transportation and control. The J-VALVES DN700 PN10 WCB flanged gate valve has become an ideal valve to meet the needs of multiple industries by virtue of its outstanding features. I. Reliable Material - WCB Carbon SteelThe select

In the current complex industrial and living scenarios, valves play a vital role in fluid control. J-VALVES stainless steel trunnion ball valves stand out among numerous industries by virtue of their unique product features and wide adaptability, and have won the praise of being "all-round valves".

In modern industrial production, fluid control is a key link to ensure the smooth progress of the production process. As an efficient and reliable fluid control device, the ear shaft ball valve is widely used in multiple fields such as petroleum, chemical engineering, natural gas and water treatment

Stainless steel high-pressure ball valves with high-pressure design and excellent sealing performance are specially designed for high-pressure environments. They can withstand extremely high pressure while maintaining excellent sealing performance. The sealing surface adopts an advanced hardened sur

Structural characteristics of trunnion ball valves. (I) Trunnion support design. The core structure of a trunnion ball valve is the trunnion support system. The ball is fixed by trunnions at the top and bottom. This design significantly reduces the friction between the ball and the valve seat, and a

Structure and working principle of floating ball valveThe core component of a floating ball valve is a floating ball. Under the action of medium pressure, the ball can produce a certain displacement and be tightly pressed against the sealing surface at the outlet end, thereby realizing sealing. This

Sealing principle of elastic gate valveThe core component of the elastic gate valve is the elastic gate. Its sealing principle is based on the elastic deformation compensation mechanism. The following are the key points of its sealing principle: I. Elastic deformation compensation The elastic gate i

I. Basic Characteristics of Floating Ball Valve(1) Structural PrincipleThe core component of the floating ball valve is a ball that can freely float within the valve body. The outer surface of the ball is machined with a sealing surface, which closely cooperates with the valve seat to achieve sealin

Application Practice of Low-temperature Trunnion Ball Valves in the LNG Field(1) LNG Receiving TerminalThe LNG receiving terminal is an important link in the liquefied natural gas industry chain, responsible for receiving, storing, and transshipping LNG. In the receiving terminal, low-temperature tr

Structural Design of Trunnion Ball Valve(1) Trunnion Support StructureDesign Principle· The core design of the trunnion ball valve is to fix the ball in the valve body through the trunnion, and the ball will not move towards the valve seat during the operation. This design significantly reduces the

Water treatment is an important link to ensure the sustainable utilization of water resources and environmental protection. In water treatment systems, valves, as key fluid control components, directly affect the operational efficiency and stability of the system. Floating ball valves have been wide