| Availability: | |

|---|---|

| Quantity: | |

Q41F

J-VALVES

ANSI 150LB ISO5211 High Pad Full Bore Flanged Type RF Stainless Steel Floating Ball Valve

ANSI 150LB ISO5211 High Pad Full Bore Flanged Type RF Stainless Steel Floating Ball Valve.The J-VALVES Style Split-Body full port flanged end ball valves employ investment or shell cast bodies & tailpieces, all produced from ASTM grade materials that are properly heat treated and chemically finished. All wall thicknesses comply with ASME B16.34 as do bolting stress levels.

Industrial and Oil/Gas piping applications requiring the higher flow capacity and lower pressure drop of full port internal flow-ways, and those applications where ease of repairability is desired.

Stainless Steel Floating Ball Valve,floating Ball Valves are designed, constructed, and tested according to API and ASME/ANSI Standards. Other international standards including BS and DIN are also available upon request.

1. ANSI 150LB ISO5211 High Pad Full Bore Flanged Type RF Stainless Steel Floating Ball Valve Technical specifications:

l. 2-Piece Bolted Body, Full Port Construction

l Fully Compliant to ASME B16.34

l Fully Compliant to API 608

l API 607 6th Edition Fire-Safe

l All Models are NACE MR0175 Compliant

l Submerged Packing System & Direct Mount Actuation

l Standard ISO Actuator Mounting Pads on All Sizes

l Standard Locking Stainless Steel Handles

l Second Generation PTFE Seats Provide Higher Operating Temperatures

l Standard Electrically Grounded Ball & Stem

2. ANSI 150LB ISO5211 High Pad Full Bore Flanged Type RF Stainless Steel Floating Ball Valve Product Specification:

l Size: 1/2''-10''(DN15~DN250)

l Pressure Rating: 150LB-600LB/PN16~PN100/10K~60K)

l Material: A351 CF8M/CF8/CF3/CF3M, A216 WCB, A352 LCB/LCC,F51/F53

l Suitable Temperature: -196ºC~450ºC( Different temperature choose different materials).

l Suitable Medium: Water, Steam, Oil and natural gas etc.

3.ANSI 150LB ISO5211 High Pad Full Bore Flanged Type RF Stainless Steel Floating Ball Valve Product Feature:

l Floating ball, full bore or reduce bore.

l ISO5211 mounting pad for option.

l Blow-out proof stem design.

l PTFE/RPTFE seat seal( Seat seal material could be decided by customer's request or according to valve's medium & temp. condition).

l Anti-static design and API 607 Fire Safe Design available

l Operation: Hand wheel, Worm wheel, Pneumatic actuator & Electric Actuator.

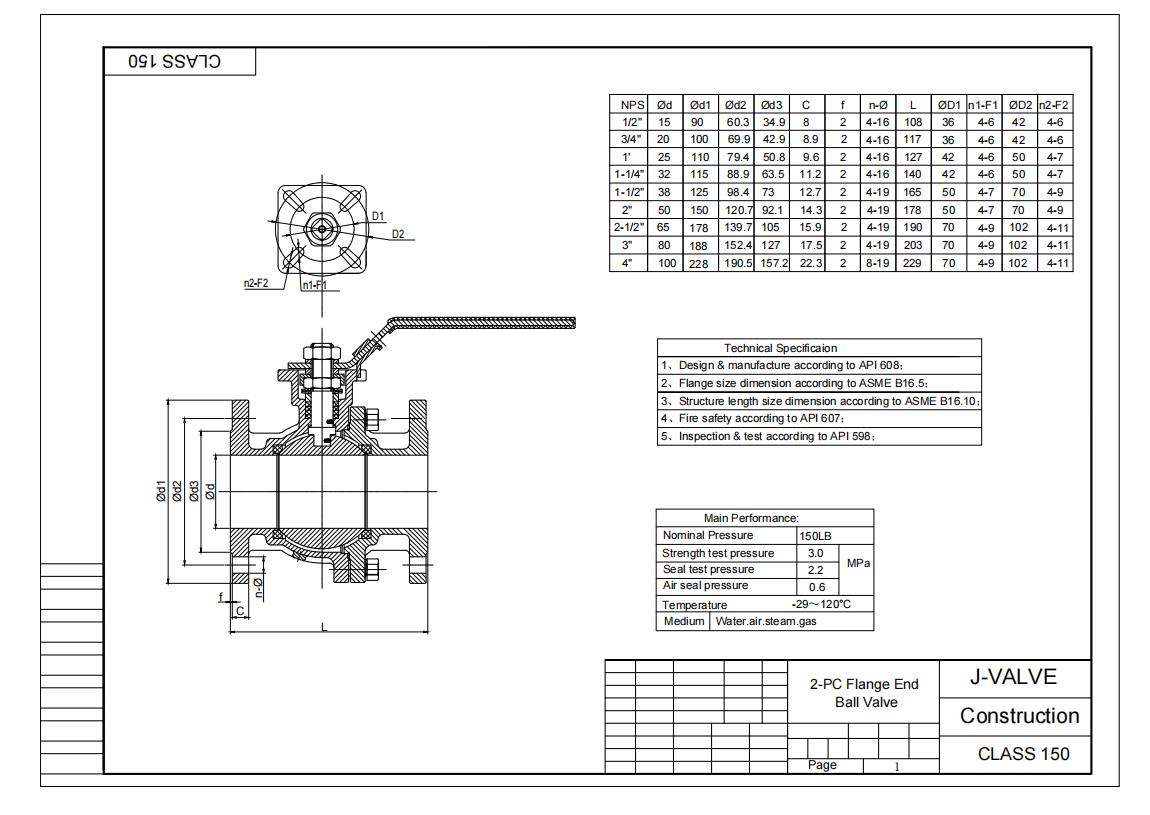

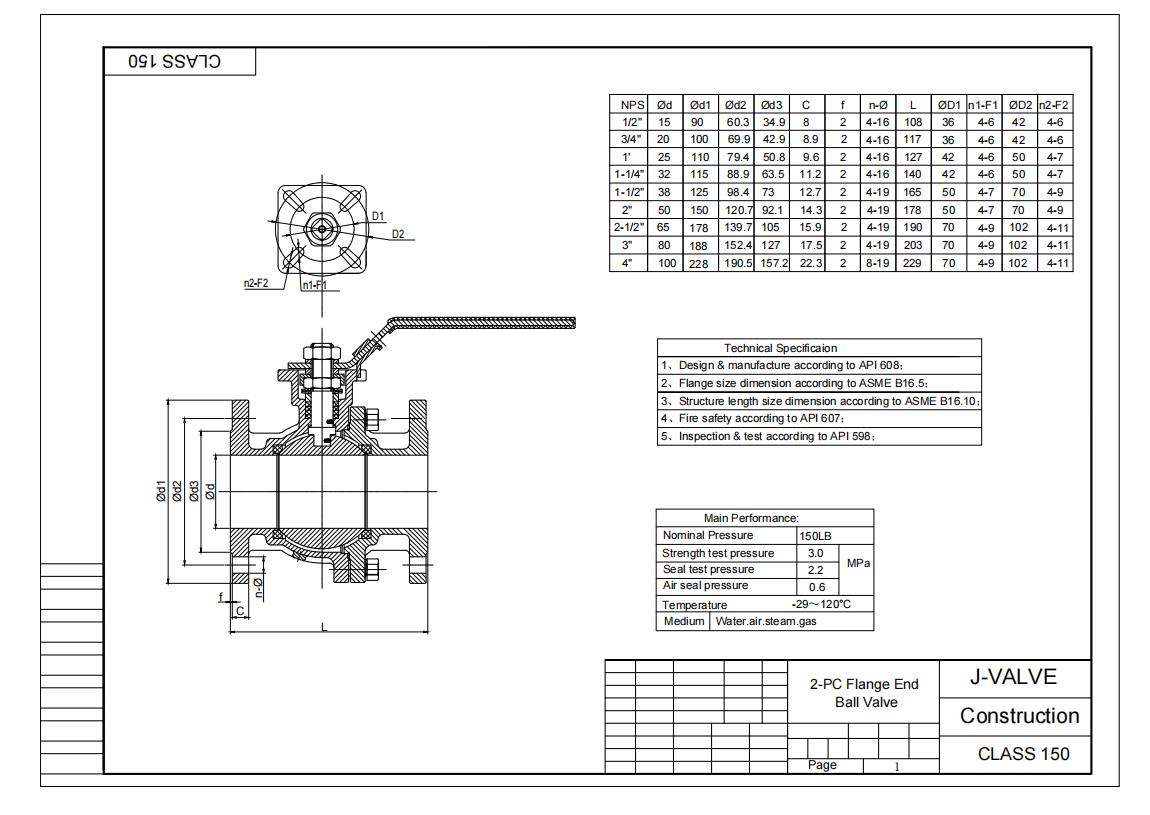

4. ANSI 150LB ISO5211 High Pad Full Bore Flanged Type RF Stainless Steel Floating Ball Valve Product Drawing:

Note: All the data should be confirmed with the approved drawings of manufacturer.

Tips:

We also manufacture other type valves, as butterfly valve, check valve, globe valve, Y strainer, sanitary butterfly valve, sanitary ball and so on.

Any item meets your interest, anything confused you, pls keep me posted, let's talk more.

J-VALVES Service:

l On Samples Buyer bear the air fee, but this fee will be reduced from order directly

l On After Sales Free replacement if there is any quality problem

l On Delivery Never delay delivery time

l On Materials Ensure material pure

l Ensure material pure

ANSI 150LB ISO5211 High Pad Full Bore Flanged Type RF Stainless Steel Floating Ball Valve

ANSI 150LB ISO5211 High Pad Full Bore Flanged Type RF Stainless Steel Floating Ball Valve.The J-VALVES Style Split-Body full port flanged end ball valves employ investment or shell cast bodies & tailpieces, all produced from ASTM grade materials that are properly heat treated and chemically finished. All wall thicknesses comply with ASME B16.34 as do bolting stress levels.

Industrial and Oil/Gas piping applications requiring the higher flow capacity and lower pressure drop of full port internal flow-ways, and those applications where ease of repairability is desired.

Stainless Steel Floating Ball Valve,floating Ball Valves are designed, constructed, and tested according to API and ASME/ANSI Standards. Other international standards including BS and DIN are also available upon request.

1. ANSI 150LB ISO5211 High Pad Full Bore Flanged Type RF Stainless Steel Floating Ball Valve Technical specifications:

l. 2-Piece Bolted Body, Full Port Construction

l Fully Compliant to ASME B16.34

l Fully Compliant to API 608

l API 607 6th Edition Fire-Safe

l All Models are NACE MR0175 Compliant

l Submerged Packing System & Direct Mount Actuation

l Standard ISO Actuator Mounting Pads on All Sizes

l Standard Locking Stainless Steel Handles

l Second Generation PTFE Seats Provide Higher Operating Temperatures

l Standard Electrically Grounded Ball & Stem

2. ANSI 150LB ISO5211 High Pad Full Bore Flanged Type RF Stainless Steel Floating Ball Valve Product Specification:

l Size: 1/2''-10''(DN15~DN250)

l Pressure Rating: 150LB-600LB/PN16~PN100/10K~60K)

l Material: A351 CF8M/CF8/CF3/CF3M, A216 WCB, A352 LCB/LCC,F51/F53

l Suitable Temperature: -196ºC~450ºC( Different temperature choose different materials).

l Suitable Medium: Water, Steam, Oil and natural gas etc.

3.ANSI 150LB ISO5211 High Pad Full Bore Flanged Type RF Stainless Steel Floating Ball Valve Product Feature:

l Floating ball, full bore or reduce bore.

l ISO5211 mounting pad for option.

l Blow-out proof stem design.

l PTFE/RPTFE seat seal( Seat seal material could be decided by customer's request or according to valve's medium & temp. condition).

l Anti-static design and API 607 Fire Safe Design available

l Operation: Hand wheel, Worm wheel, Pneumatic actuator & Electric Actuator.

4. ANSI 150LB ISO5211 High Pad Full Bore Flanged Type RF Stainless Steel Floating Ball Valve Product Drawing:

Note: All the data should be confirmed with the approved drawings of manufacturer.

Tips:

We also manufacture other type valves, as butterfly valve, check valve, globe valve, Y strainer, sanitary butterfly valve, sanitary ball and so on.

Any item meets your interest, anything confused you, pls keep me posted, let's talk more.

J-VALVES Service:

l On Samples Buyer bear the air fee, but this fee will be reduced from order directly

l On After Sales Free replacement if there is any quality problem

l On Delivery Never delay delivery time

l On Materials Ensure material pure

l Ensure material pure

Overview of ASME B16.34 Ball ValvesStandard and ApplicationASME B16.34 is a widely recognized standard for ball valves, developed by the American Society of Mechanical Engineers (ASME). It covers the design, manufacturing, and testing of ball valves with flanged, threaded, and welding end connection

Overview of Ball Valves (API 6D)Definition and ApplicationAPI 6D ball valves are quarter-turn valves designed for pipeline and industrial applications. They are known for their robustness and ability to handle high-pressure and high-flow conditions, making them ideal for critical operations in the o

Introduction to Bronze ValvesBronze valves are widely used in various industries, including plumbing, marine, chemical processing, and more. These valves are valued for their ability to withstand harsh environments, resist corrosion, and maintain functionality over extended periods. The choice of br

Gate valves and butterfly valves are two common types of valves, and each of them has different advantages and disadvantages. The following is a detailed introduction for you

Among numerous types of valves, both the cast steel flanged gate valve and the butterfly valve are common choices in industrial and various pipeline systems. However, when we conduct an in-depth comparison between the J-VALVES cast steel flanged gate valve and the butterfly valve, we will find that the former has significant advantages in terms of high-efficiency opening and closing functions, and a series of intuitive data serves as powerful proof.

I. Basic Principle and Structure of Floating Ball ValveThe core component of a floating ball valve is a ball with a passage. Under the action of medium pressure, the ball can freely float between the valve seats. When the valve is opened, the passage of the ball aligns with the pipeline, allowing th

The C95800 bronze ball valve is a high-performance valve product, widely used in working environments with corrosive media such as seawater, concentrated brine, sulfate and various chloride solutions. Its selection requires a comprehensive consideration of multiple factors to ensure the performance,

Overview of ANSI/API 6081.1 Scope and Application• Scope: API 608 is an American standard that specifies the requirements for metal ball valves with flanged, threaded, and butt-welded end connections. It is widely used in the oil, gas, and petrochemical industries.• Applications: Suitable for proces

The pneumatic butt welded ball valve is a type of valve that controls the on-off of the fluid by driving the rotation of the ball through a pneumatic actuator. It has the advantages of rapid opening and closing, good sealing performance and convenient operation, and is suitable for various industria

High voltage design and excellent sealing performanceStainless steel high-pressure ball valves are specifically designed for high-pressure environments and can withstand extremely high pressures while maintaining excellent sealing performance. Its sealing surface adopts an advanced hardened surfacin

1. Material SelectionMaterial selection is the first and most critical step in manufacturing B62 bronze ball valves. The primary material used is C83600 tin bronze, known for its high tensile strength, excellent corrosion resistance, and good machinability.• Chemical Composition: C83600 bronze typic

Overview of API 6D and GB/T 12237 Standards1.1 API 6D Standard• Scope: API 6D is a globally recognized specification for pipeline valves, particularly for the petroleum and natural gas industries. It covers ball valves, gate valves, plug valves, and check valves with pressure ratings up to Class 250

Understanding API 6DAPI 6D is a comprehensive standard specifically designed for pipeline valves used in the transportation of oil, gas, and other liquids. It covers various types of valves, including ball valves, gate valves, globe valves, check valves, and plug valves. For ball valves, API 6D prov

Ball valves are essential components in a wide range of industrial applications, from oil and gas to chemical processing and water treatment. Two prominent standards for ball valve design and manufacturing are ASME B16.34 (American Standard) and EN (European Standard) specifications. Each standard h

High-pressure ball valves are critical components in various industrial applications, particularly in the oil and gas, petrochemical, and power generation sectors. These valves are designed to control fluid flow under high-pressure conditions, ensuring reliability and safety. Two common pressure cla

Ball valves are essential components in various industrial applications, including oil and gas, petrochemical, and water treatment systems. Two prominent standards for ball valve design are API 6D (American Petroleum Institute) and DIN 3357 (Deutsches Institut für Normung).API 6D: Pressure-Temperatu

1. Overview of the Standards1.1 ASME B16.34• Issuing Body: American Society of Mechanical Engineers (ASME)• Scope: Applicable to ball valves with flanged, threaded, and welded end connections, used extensively in industries such as oil, gas, chemical, and power.• Content: Covers pressure-temperature

Bolted Flange DesignDesign PrinciplesBolted flange designs use bolts to compress a gasket between the valve cover and body. The gasket, typically made of graphite or PTFE, provides flexibility and sealing properties. Proper bolt tightening is essential for a reliable seal.Pressure-Assisted Self-Seal

In the industrial sector, particularly in the petroleum, petrochemical, and natural gas industries, ball valves play a crucial role in controlling fluid flow within pipeline systems. To ensure reliability, safety, and compatibility, these valves must adhere to stringent design and manufacturing stan

Ball valves are essential components in the petrochemical industry, used to control fluid flow in various pipeline systems. Two prominent standards, API 6D and ASME B16.34, provide guidelines to ensure the quality, performance, and safety of these valves.API 6D: Key Requirements1. ScopeAPI 6D (Speci