| Availability: | |

|---|---|

| Quantity: | |

2“-48”

J-VALVES

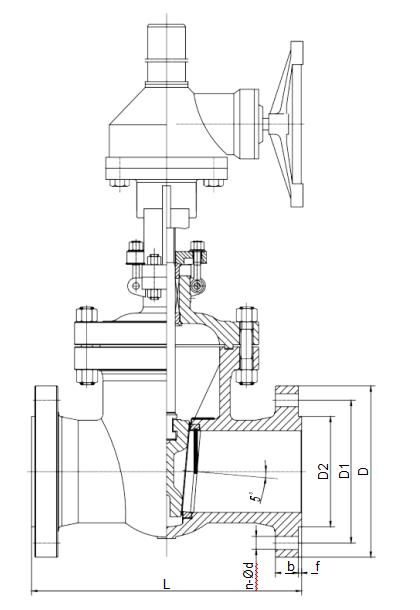

Structural Features

Cast Steel Material: The valve body is made of high-quality cast steel (e.g., ASTM A216 WCB), which has high strength and good corrosion resistance. It can resist the erosion of various chemical media and extend the service life of the valve.

Flange Connection: Adopts a standard flange connection method, compliant with the ASME B16.5 standard, ensuring reliable installation and tight sealing.

Gear Operation: Equipped with a gear operating mechanism, it provides stable opening and closing performance, reduces operating torque, and is suitable for large-diameter and high-pressure working conditions.

Bidirectional Sealing: The unique sealing design ensures reliable sealing during both forward and reverse flow, effectively preventing medium leakage and ensuring the safe operation of the pipeline system.

Fire-Safe Design: Complies with the API 607 standard. Even in case of fire, the valve can maintain sealing performance to prevent medium leakage and ensure system safety.

Anti-Static Device: Built-in anti-static device effectively prevents static accumulation, reduces the risk of fire and explosion, and is particularly suitable for controlling flammable and explosive media.

Compact Design: Small in size and light in weight, it is easy to install and integrate into existing systems, saving space.

Technical Parameters

Nominal Diameter: 24″ (DN600)

Pressure Rating: 600LB

Temperature Range: -29℃ to +425℃

Materials:

Valve Body: Cast steel (ASTM A216 WCB)

Gate Disc: Stainless steel (304/316)

Valve Stem: Stainless steel (304/316)

Sealing Material: PTFE, RPTFE

Connection Type: Flange connection (compliant with ASME B16.47 standard)

Operation Mode: Gear operation

Design Standards: API 600, ASME B16.34

Testing Standards: API 598, ISO 5208

Fire-Safe Design: API 607

Applicable Media: Oil, natural gas, water, steam, chemical media, etc.

Application Scenarios

Oil and Gas Industry: Used in oil and gas field exploration, gathering, transportation, and processing systems to ensure reliable isolation and control of media.

Chemical Industry: Suitable for conveying and reaction systems of various chemical media, preventing medium leakage and ensuring production safety.

Pharmaceutical Industry: Applied in pipeline systems during pharmaceutical production to ensure medium isolation and cleanliness in the drug manufacturing process.

Food and Beverage Industry: Meets food-grade requirements, used in pipeline systems for food and beverage production to ensure hygiene and safety.

HVAC: Used in cooling water systems, hot water systems, etc., to ensure efficient operation of the system.

General Industrial Applications: Suitable for controlling and isolating media such as water, oil, and gas.

Advantages and Value

High Reliability: The cast steel material and gear-operated design ensure the valve operates stably in high-pressure and medium-to-high temperature environments, reducing maintenance frequency and downtime.

High Safety: Fire-resistant and anti-static designs, along with reliable sealing performance, effectively reduce leakage risks and protect the safety of personnel and equipment.

Automated Compatibility: The gear operating mechanism provides stable opening and closing performance, suitable for large-diameter and high-pressure working conditions.

Easy Installation and Maintenance: The flange connection simplifies the installation process and facilitates maintenance and overhaul.

Wide Applicability: Multiple material options and a broad range of pressure and temperature ratings allow the valve to adapt to various complex working conditions and medium characteristics.

Specifications:

J-VALVES Competitive Advantage:

On Samples Buyer bear the air fee, but this fee will be reduced from order directly

On After Sales Free replacement if there is any quality problem

On Delivery Never delay delivery time

On Materials Ensure material pure

Ensure material pure

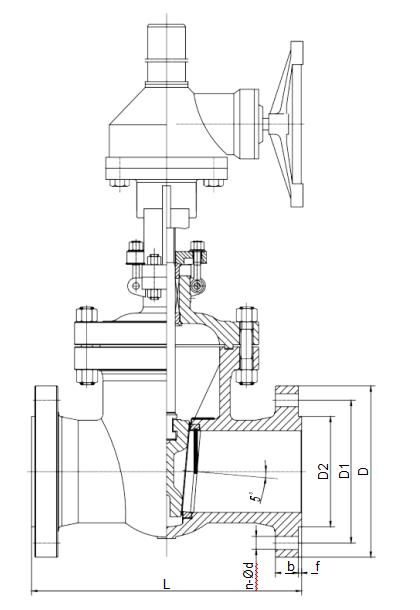

Structural Features

Cast Steel Material: The valve body is made of high-quality cast steel (e.g., ASTM A216 WCB), which has high strength and good corrosion resistance. It can resist the erosion of various chemical media and extend the service life of the valve.

Flange Connection: Adopts a standard flange connection method, compliant with the ASME B16.5 standard, ensuring reliable installation and tight sealing.

Gear Operation: Equipped with a gear operating mechanism, it provides stable opening and closing performance, reduces operating torque, and is suitable for large-diameter and high-pressure working conditions.

Bidirectional Sealing: The unique sealing design ensures reliable sealing during both forward and reverse flow, effectively preventing medium leakage and ensuring the safe operation of the pipeline system.

Fire-Safe Design: Complies with the API 607 standard. Even in case of fire, the valve can maintain sealing performance to prevent medium leakage and ensure system safety.

Anti-Static Device: Built-in anti-static device effectively prevents static accumulation, reduces the risk of fire and explosion, and is particularly suitable for controlling flammable and explosive media.

Compact Design: Small in size and light in weight, it is easy to install and integrate into existing systems, saving space.

Technical Parameters

Nominal Diameter: 24″ (DN600)

Pressure Rating: 600LB

Temperature Range: -29℃ to +425℃

Materials:

Valve Body: Cast steel (ASTM A216 WCB)

Gate Disc: Stainless steel (304/316)

Valve Stem: Stainless steel (304/316)

Sealing Material: PTFE, RPTFE

Connection Type: Flange connection (compliant with ASME B16.47 standard)

Operation Mode: Gear operation

Design Standards: API 600, ASME B16.34

Testing Standards: API 598, ISO 5208

Fire-Safe Design: API 607

Applicable Media: Oil, natural gas, water, steam, chemical media, etc.

Application Scenarios

Oil and Gas Industry: Used in oil and gas field exploration, gathering, transportation, and processing systems to ensure reliable isolation and control of media.

Chemical Industry: Suitable for conveying and reaction systems of various chemical media, preventing medium leakage and ensuring production safety.

Pharmaceutical Industry: Applied in pipeline systems during pharmaceutical production to ensure medium isolation and cleanliness in the drug manufacturing process.

Food and Beverage Industry: Meets food-grade requirements, used in pipeline systems for food and beverage production to ensure hygiene and safety.

HVAC: Used in cooling water systems, hot water systems, etc., to ensure efficient operation of the system.

General Industrial Applications: Suitable for controlling and isolating media such as water, oil, and gas.

Advantages and Value

High Reliability: The cast steel material and gear-operated design ensure the valve operates stably in high-pressure and medium-to-high temperature environments, reducing maintenance frequency and downtime.

High Safety: Fire-resistant and anti-static designs, along with reliable sealing performance, effectively reduce leakage risks and protect the safety of personnel and equipment.

Automated Compatibility: The gear operating mechanism provides stable opening and closing performance, suitable for large-diameter and high-pressure working conditions.

Easy Installation and Maintenance: The flange connection simplifies the installation process and facilitates maintenance and overhaul.

Wide Applicability: Multiple material options and a broad range of pressure and temperature ratings allow the valve to adapt to various complex working conditions and medium characteristics.

Specifications:

J-VALVES Competitive Advantage:

On Samples Buyer bear the air fee, but this fee will be reduced from order directly

On After Sales Free replacement if there is any quality problem

On Delivery Never delay delivery time

On Materials Ensure material pure

Ensure material pure

Understanding Gate Valve Design StandardsKey Standards and SpecificationsGate valves are governed by several international and national standards that define their design, manufacturing, testing, and performance characteristics. Some of the most commonly referenced standards include:• ANSI/ASME B16.

Flow Rate and Pressure DropFlow RateDefinition: The flow rate is the volume of fluid that passes through the valve per unit of time.Importance: Ensuring the check valve can handle the required flow rate without excessive pressure drop is essential for maintaining system efficiency.Considerations: Se

Welding Technology for Gate ValvesWelding Process SelectionChoosing the appropriate welding process is essential for achieving high-quality welds in gate valves. The most commonly used welding processes include:Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW is a versatile proce

In modern industrial production, fluid control is a key link to ensure the smooth progress of the production process. As an efficient and reliable fluid control device, the ear trunnion ball valve is widely used in multiple fields such as petroleum, chemical engineering, natural gas and water treatm

What Makes C95800 Bronze So Special?C95800, also known as aluminum bronze, is a high-performance alloy renowned for its exceptional mechanical properties:Unmatched Wear Resistance: The alloy's unique composition—rich in copper, aluminum, iron, and nickel—creates a dense, hard surface that resists sc

1. Understanding Pressure Ratings (PN16 to PN100)The pressure rating of a floating flange ball valve is expressed in PN, where PN16 indicates a valve rated for 16 bar (or approximately 232 psi) and PN100 indicates a valve rated for 100 bar (or approximately 1450 psi). These ratings are determined by

Understanding Y-Type and Basket StrainersY-Type StrainersStructure and FunctionY-type strainers consist of a cylindrical body, a Y-shaped strainer basket, and connections for inlet and outlet pipes. The strainer basket, typically made of perforated metal or mesh, allows fluid to pass through while t

Project Case Study: Reliable Solid Particle Protection for Industrial PipelinesProject BackgroundIn recent years, wastewater treatment and reuse projects in Kazakhstan have continued to expand, especially in municipal infrastructure, mining support systems, and industrial process water applications.

In modern industrial fluid control systems, material selection often determines the service life and safety of the system. The ASTM B62 Bronze Gate Valve has become a core component in marine engineering, heating, ventilation, and air conditioning (HVAC) as well as water supply and drainage systems,

In the realm of industrial fluid handling, stainless steel Y-type strainers stand as a cornerstone of system reliability, efficiency, and longevity. Engineered to remove debris, particles, and contaminants from pipelines, these devices play a pivotal role in safeguarding equipment, reducing downtime

Structure and Working Principle of Double Disc Bronze Check ValveThe double disc bronze check valve is mainly composed of a valve body, two half-disc valve discs, a hinge mechanism, and sealing surfaces. The discs are connected by hinges and installed inside the valve body, enabling them to automati

In industrial fluid systems, filters are critical components that ensure system cleanliness and prevent contaminants from entering. The J-VALVES 2" 600LB CF8M Y-Type Filter is a high-efficiency, reliable filtration solution suitable for a wide range of industrial applications.1. High Pressure Resist

In industrial production, high temperature working conditions impose extremely stringent requirements on the performance of equipment. Especially in the filtration process involving high-temperature fluids, it is crucial to choose the appropriate filter material and model. Y-type strainer made of nickel aluminum bronze B148 (C95800) material have become the first choice for many engineers due to their excellent high temperature resistance and corrosion resistance.

What is a B62 Bronze Gate Valve?The B62 Bronze Gate Valve is a type of gate valve designed for industrial use, primarily in fluid control systems. Constructed from Ni-Al bronze, it offers excellent resistance to corrosion, high temperature, and pressure, making it an ideal choice for demanding envir

In the field of shipbuilding, seawater filtration is an important link to ensure the normal operation of key systems of ships. As a high-performance seawater filtration device, the C95800 strainer has become an indispensable component in shipbuilding due to its outstanding corrosion resistance, high

What Are Gate Valves?A gate valve is a type of valve that uses a sliding gate to control the flow of fluid. The gate moves vertically within the valve body to open or close the passage. When fully open, the gate valve creates a straight path for the flow of fluids, allowing minimal pressure drop. Ga

In modern industrial fluid control systems, tiny impurities are often the "invisible killers" that cause costly equipment failures. Founded in 2009, J-VALVES has been committed to the R&D and manufacturing of industrial valve solutions. Among our products, the Y-Strainer has become a core component for protecting pumps, compressors, and instrumentation systems due to its exceptional filtration efficiency and durability.

Understanding J-VALVES High-Performance Gate ValvesJ-VALVES' high-performance gate valves are designed with advanced engineering principles to ensure they can withstand the rigors of industrial use. These valves are available in a variety of sizes, materials, and configurations, allowing them to be

Selection Guide(1) Selection Based on Fluid CharacteristicsLiquid: If the fluid is water or a low-viscosity liquid with few impurities, a Y-type strainer can be selected; if the fluid is oil or contains a large amount of impurities, it is recommended to choose a basket strainer.Gas: For gas filtrati

In process systems such as petrochemical, industrial water treatment, energy, power, and fine chemical industries, pipeline clogging due to impurities remains one of the core issues affecting stable system operation. Once welding slag, rust, sand particles, or solid debris enter the pipeline, they not only cause valve jamming and pump wear but may also lead to unplanned shutdowns, resulting in high maintenance costs.