| Availability: | |

|---|---|

| Quantity: | |

2“-56”

J-VALVES

Structural Features

Trunnion Design: Adopts a fixed ball and trunnion structure, which reduces operating torque, improves the valve’s reliability and durability, and ensures stable operation in high-pressure environments.

Gear Operation: Equipped with a gear operating mechanism, it provides stable opening and closing performance, reduces operating torque, and is suitable for large-diameter and high-pressure working conditions.

Fire-Safe Design: Complies with the API 607 standard. Even in case of fire, the valve can maintain sealing performance to prevent medium leakage and ensure system safety.

Anti-Static Device: Built-in anti-static device effectively prevents static accumulation, reduces the risk of fire and explosion, and is particularly suitable for controlling flammable and explosive media.

Compact Design: Small in size and light in weight, it is easy to install and integrate into existing systems, saving space.

Multiple Connection Methods: Offers multiple connection methods such as flange connection and butt weld (BW) connection to meet different engineering requirements.

Multiple Operation Modes: Can be equipped with manual, pneumatic, electric, or hydraulic actuators to achieve remote and automated control.

Technical Parameters

Nominal Diameter: 2″ to 56″ (DN50 to DN1400)

Pressure Rating: 150LB to 2500LB (PN10 to PN420)

Temperature Range: -196℃ to +450℃

Materials:

Valve Body: Carbon Steel (WCB), Stainless Steel (304, 316), Alloy Steel

Ball: Stainless Steel (304, 316)

Valve Stem: Stainless Steel (304, 316)

Sealing Material: PTFE, RPTFE

Connection Type: Flange connection (compliant with ASME B16.5 standard), Butt Weld (BW) connection

Operation Mode: Gear Operation

Design Standards: API 6D, ASME B16.34

Testing Standards: API 598, ISO 5208

Fire-Safe Design: API 607

Applicable Media: Water, oil, gas, chemical media, etc.

Application Scenarios

Oil and Natural Gas Industry: Used in oil and gas field exploration, gathering, transportation, and processing systems to ensure reliable isolation and control of media.

Chemical Industry: Suitable for conveying and reaction systems of various chemical media, preventing medium leakage and ensuring production safety.

Pharmaceutical Industry: Applied in pipeline systems during pharmaceutical production to ensure medium isolation and cleanliness in the drug manufacturing process.

Food and Beverage Industry: Meets food-grade requirements, used in pipeline systems for food and beverage production to ensure hygiene and safety.

HVAC: Used in cooling water systems, hot water systems, etc., to ensure efficient operation of the system.

General Industrial Applications: Suitable for controlling and isolating media such as water, oil, and gas.

Advantages and Value

High Reliability: The trunnion design and gear operating mechanism ensure the valve operates stably in medium-high pressure and medium-high temperature environments, reducing maintenance frequency and downtime.

High Safety: Fire-resistant and anti-static designs, along with reliable sealing performance, effectively reduce leakage risks and protect the safety of personnel and equipment.

Operational Convenience: The gear operating mechanism provides stable opening and closing performance, reduces operating torque, and is suitable for large-diameter and high-pressure working conditions.

Easy Installation and Maintenance: The flange connection simplifies the installation process and facilitates maintenance and overhaul.

Wide Applicability: Multiple material options and a broad range of pressure and temperature ratings allow the valve to adapt to various complex working conditions and medium characteristics.

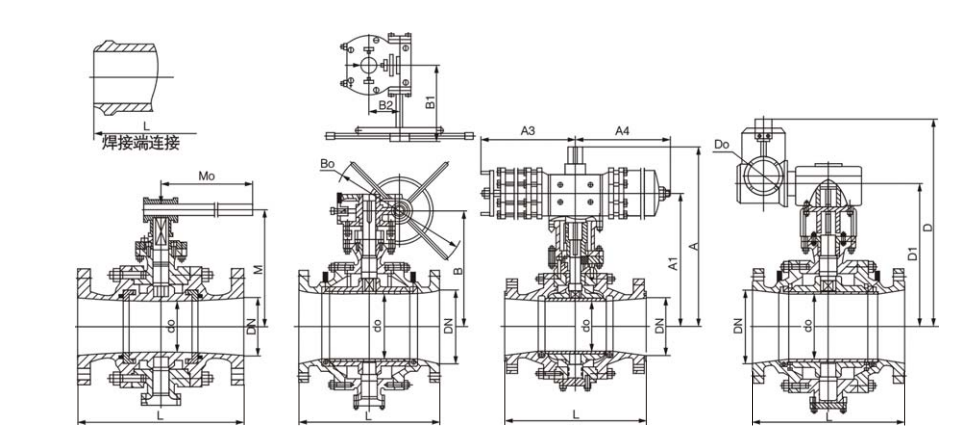

Big Size API6D Trunnion Ball Valve Product Drawing:

Note: All the data should be confirmed with the approved drawings of manufacturer.

Tips:

We also manufacture other type valves, as butterfly valve, check valve, globe valve, Y strainer, sanitary butterfly valve, sanitary ball and so on.

Any item meets your interest, anything confused you, pls keep me posted, let's talk more.

J-VALVES Service:

On Samples Buyer bear the air fee, but this fee will be reduced from order directly

On After Sales Free replacement if there is any quality problem

On Delivery Never delay delivery time

On Materials Ensure material pure

Ensure material pure

Structural Features

Trunnion Design: Adopts a fixed ball and trunnion structure, which reduces operating torque, improves the valve’s reliability and durability, and ensures stable operation in high-pressure environments.

Gear Operation: Equipped with a gear operating mechanism, it provides stable opening and closing performance, reduces operating torque, and is suitable for large-diameter and high-pressure working conditions.

Fire-Safe Design: Complies with the API 607 standard. Even in case of fire, the valve can maintain sealing performance to prevent medium leakage and ensure system safety.

Anti-Static Device: Built-in anti-static device effectively prevents static accumulation, reduces the risk of fire and explosion, and is particularly suitable for controlling flammable and explosive media.

Compact Design: Small in size and light in weight, it is easy to install and integrate into existing systems, saving space.

Multiple Connection Methods: Offers multiple connection methods such as flange connection and butt weld (BW) connection to meet different engineering requirements.

Multiple Operation Modes: Can be equipped with manual, pneumatic, electric, or hydraulic actuators to achieve remote and automated control.

Technical Parameters

Nominal Diameter: 2″ to 56″ (DN50 to DN1400)

Pressure Rating: 150LB to 2500LB (PN10 to PN420)

Temperature Range: -196℃ to +450℃

Materials:

Valve Body: Carbon Steel (WCB), Stainless Steel (304, 316), Alloy Steel

Ball: Stainless Steel (304, 316)

Valve Stem: Stainless Steel (304, 316)

Sealing Material: PTFE, RPTFE

Connection Type: Flange connection (compliant with ASME B16.5 standard), Butt Weld (BW) connection

Operation Mode: Gear Operation

Design Standards: API 6D, ASME B16.34

Testing Standards: API 598, ISO 5208

Fire-Safe Design: API 607

Applicable Media: Water, oil, gas, chemical media, etc.

Application Scenarios

Oil and Natural Gas Industry: Used in oil and gas field exploration, gathering, transportation, and processing systems to ensure reliable isolation and control of media.

Chemical Industry: Suitable for conveying and reaction systems of various chemical media, preventing medium leakage and ensuring production safety.

Pharmaceutical Industry: Applied in pipeline systems during pharmaceutical production to ensure medium isolation and cleanliness in the drug manufacturing process.

Food and Beverage Industry: Meets food-grade requirements, used in pipeline systems for food and beverage production to ensure hygiene and safety.

HVAC: Used in cooling water systems, hot water systems, etc., to ensure efficient operation of the system.

General Industrial Applications: Suitable for controlling and isolating media such as water, oil, and gas.

Advantages and Value

High Reliability: The trunnion design and gear operating mechanism ensure the valve operates stably in medium-high pressure and medium-high temperature environments, reducing maintenance frequency and downtime.

High Safety: Fire-resistant and anti-static designs, along with reliable sealing performance, effectively reduce leakage risks and protect the safety of personnel and equipment.

Operational Convenience: The gear operating mechanism provides stable opening and closing performance, reduces operating torque, and is suitable for large-diameter and high-pressure working conditions.

Easy Installation and Maintenance: The flange connection simplifies the installation process and facilitates maintenance and overhaul.

Wide Applicability: Multiple material options and a broad range of pressure and temperature ratings allow the valve to adapt to various complex working conditions and medium characteristics.

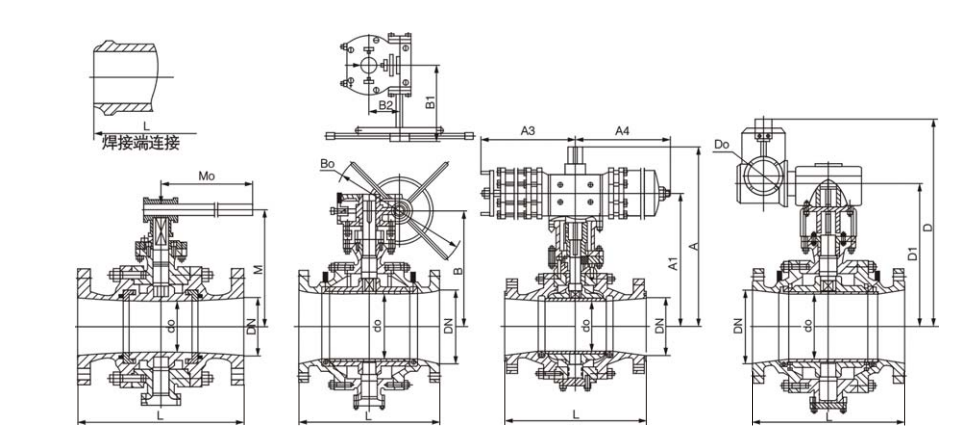

Big Size API6D Trunnion Ball Valve Product Drawing:

Note: All the data should be confirmed with the approved drawings of manufacturer.

Tips:

We also manufacture other type valves, as butterfly valve, check valve, globe valve, Y strainer, sanitary butterfly valve, sanitary ball and so on.

Any item meets your interest, anything confused you, pls keep me posted, let's talk more.

J-VALVES Service:

On Samples Buyer bear the air fee, but this fee will be reduced from order directly

On After Sales Free replacement if there is any quality problem

On Delivery Never delay delivery time

On Materials Ensure material pure

Ensure material pure

In the field of industrial pipeline systems, especially in the petroleum, natural gas, and large-scale water treatment industries, large size trunnion ball valves that comply with API 6D standards have become the core equipment for fluid control and isolation. API 6D, formulated by the American Petroleum Institute (API), is a globally recognized authoritative standard for pipeline valves, defining strict requirements for the design, manufacturing, assembly, testing, and documentation of valves. For large-diameter pipeline projects, the stability, pressure-bearing capacity, and sealing performance of valves directly affect the safety and efficiency of the entire system.

Understanding Water HammerDefinition and ImpactWater hammer occurs when fluid flow in a pipeline is suddenly stopped or redirected, causing a pressure wave to propagate through the fluid. This can result in significant pressure spikes, leading to pipe rupture, valve failure, and other damage.Causes

Gate valves with pneumatic actuators are a type of gate valve that uses pneumatic actuation devices for opening and closing operations, and are widely applied in industrial systems requiring remote or automated control. Pneumatic actuators provide efficient and precise control capabilities for gate

Welded metal-sealed triple eccentric butterfly valves are advanced industrial valves widely applied in piping systems requiring high sealing performance, high temperature and corrosion resistance. The design of such valves integrates metal sealing technology with a triple eccentric structure, ensuri

When selecting reliable floating ball valves for highly corrosive and demanding industrial applications such as marine engineering, offshore oil and gas, chemical processing, or seawater treatment, engineers and purchasers prioritize three core factors: material durability, compliance with international standards, and long-term operational stability. J-VALVES API608 C95800 Floating Ball Valve is engineered to meet and exceed these requirements. Leveraging the exceptional performance of C95800 nickel-aluminum bronze alloy and strictly adhering to the API 608 standard, it delivers unparalleled performance in harsh environments. As a trusted choice in the global industrial sector, this valve addresses the most common pain points in industrial fluid control, making it the premier solution for applications requiring corrosion resistance, high pressure tolerance, and high reliability.

In industrial piping systems, with the continuous increase of pipe diameters and pressure ratings, the selection of ball valve structural forms becomes particularly critical. While floating ball valves are widely used in small-diameter working conditions, trunnion ball valves are often a more reliable and mature solution for large-diameter, high-pressure systems.

In modern industrial piping systems, large-diameter ball valves not only perform on-off functions but also are directly related to the operational safety, sealing reliability and long-term stability of the system. Especially in occasions involving high temperature, fire hazards or complex working conditions, the safety design of valves is particularly critical.

Y-strainers are widely used devices in fluid piping systems, primarily designed to remove impurities and particulate matter from pipelines and ensure the normal operation of fluid systems. Named for their Y-shaped configuration, these strainers utilize mechanical filtration to effectively trap solid

When procuring Double Block and Bleed (DBB) ball valves for critical industrial applications, partnering with an industry-leading manufacturer like J-VALVES—with over a decade of expertise since 2009—guarantees product reliability, safety and performance. This procurement guide details the key considerations for selecting J-VALVES DBB ball valves, empowering procurement teams to make informed decisions that align with operational requirements and compliance standards.

The 150LB C95800 Strainer is a crucial component in fluid and gas control systems, designed to protect downstream equipment by filtering out debris, particulates, and other impurities from the flow. Manufactured from high-quality C95800 bronze, it is ideal for use in applications where durability an

In industrial applications, filters play a crucial role in ensuring the smooth and efficient operation of systems by preventing contaminants from damaging the internal mechanisms. The 300LB WCB filters, designed with durable cast steel, provide superior performance in high-pressure systems. What is

As a type of industrial valve with high performance and reliability, fully welded ball valves are widely used in the petroleum, natural gas, chemical, metallurgical, electric power and other industries. It is crucial to ensure the reliability of their performance before installation and commissionin

On the evening of January 31st, bathed in bright and warm lights, the 2025 J-VALVES Annual Gala with the theme On the Road, Heading for the World kicked off in grand style! All members of the J-VALVES family gathered together, shedding the toil and weariness of the whole year, and carrying our gains and honors. We looked back on our journey side by side amid laughter and joy, and marched toward a brand-new future with united striving, sharing this exclusive reunion feast and pledge of progress that belongs to us all.<br />

Understanding Gate Valve Design StandardsKey Standards and SpecificationsGate valves are governed by several international and national standards that define their design, manufacturing, testing, and performance characteristics. Some of the most commonly referenced standards include:• ANSI/ASME B16.

Flow Rate and Pressure DropFlow RateDefinition: The flow rate is the volume of fluid that passes through the valve per unit of time.Importance: Ensuring the check valve can handle the required flow rate without excessive pressure drop is essential for maintaining system efficiency.Considerations: Se

Welding Technology for Gate ValvesWelding Process SelectionChoosing the appropriate welding process is essential for achieving high-quality welds in gate valves. The most commonly used welding processes include:Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW is a versatile proce

In modern industrial production, fluid control is a key link to ensure the smooth progress of the production process. As an efficient and reliable fluid control device, the ear trunnion ball valve is widely used in multiple fields such as petroleum, chemical engineering, natural gas and water treatm

What Makes C95800 Bronze So Special?C95800, also known as aluminum bronze, is a high-performance alloy renowned for its exceptional mechanical properties:Unmatched Wear Resistance: The alloy's unique composition—rich in copper, aluminum, iron, and nickel—creates a dense, hard surface that resists sc

1. Understanding Pressure Ratings (PN16 to PN100)The pressure rating of a floating flange ball valve is expressed in PN, where PN16 indicates a valve rated for 16 bar (or approximately 232 psi) and PN100 indicates a valve rated for 100 bar (or approximately 1450 psi). These ratings are determined by

Understanding Y-Type and Basket StrainersY-Type StrainersStructure and FunctionY-type strainers consist of a cylindrical body, a Y-shaped strainer basket, and connections for inlet and outlet pipes. The strainer basket, typically made of perforated metal or mesh, allows fluid to pass through while t