| Availability: | |

|---|---|

J-VALVES-BV-300

J-VALVES

8481804090

Designed for general industrial use, this floating ball valve combines WCB carbon steel’s structural strength with a modular two - piece body. The flanged connections simplify installation in high - flow systems, while the floating ball design provides dynamic sealing under pressure. Suitable for non - corrosive media, it offers zero leakage and low - torque operation in pipelines requiring frequent switching.

Product Name | Control Gas Carbon Steel WCB 6'' 300LB 2PC Flanged Floating Ball Valve |

Material | Stainless Steel/Duplex steel/Aluminium Bronze/Nickel-aluminum Bronze/Titanium Alloy, etc. |

Pressure | 150LB~2500LB |

Size | 1/2 inch~ 24 inch(DN15~DN600) |

End Connection | RF/RTJ/BW/SW |

Working Temp | -196ºC~400ºC option. |

Mode of operation | Hand wheel, Worm wheel, Pneumatic actuator & Electric Actuator. |

Suitable Medium | Water,Natural Gas,Oil and some corrosive liquid |

Features | Anti-blow out stem, Anti-statstic, Fire safe |

Modular Two - Piece Design for Easy Maintenance

The split - body construction allows field replacement of the ball, seats, or stem in ≤45 minutes without pipeline disassembly. This reduces maintenance downtime by 60% in power plants and water treatment facilities, where system shutdowns cost $150,000/hour. The design also enables quick cleaning of internal components in food & beverage processing.

Dynamic Sealing Under Pressure

A floating ball with self - adjusting PTFE seats compensates for pressure fluctuations, ensuring bidirectional bubble - tight sealing (ISO 5208 Class A). This is critical for oil refineries and gas distribution networks, where pressure surges can damage conventional valves. CFD analysis confirms consistent sealing even at 1.5x rated pressure, preventing product loss.

High - Temperature Performance

WCB carbon steel (ASTM A216) withstands temperatures up to 425°C, outperforming standard cast iron by 35%. This makes it suitable for steam lines in power plants, hot water systems in district heating, and asphalt production units. Independent tests show no creep deformation after 10,000 hours at 400°C.

Fire - Safe Compliance & Antistatic Features

Meets API 607 fire - safe standards with graphite packing and a stainless steel antistatic device. The latter prevents electrostatic buildup in flammable media like propane and ethylene, reducing ignition risks in storage terminals. Tests confirm zero leakage after 10 minutes of flame exposure, ensuring compliance with OSHA and EPA regulations.

Low - Torque Operation

A bevel gear mechanism reduces operating torque by 30% compared to manual valves, enabling single - operator operation even in 6" sizes. This is crucial for offshore platforms and remote pipelines, where accessibility is limited. The design also minimizes wear on internal components, extending service life to 15+ years.

Corrosion - Resistant Coatings

Optional fusion - bonded epoxy (FBE) coating (ISO 12944 - 5 C5 - M) provides 300% longer service life in aggressive environments compared to standard painting. Case studies show this coating prevents chloride - induced pitting in coastal power plants and sulfuric acid corrosion in fertilizer production.

Quality Assurance: Our valves are manufactured in accordance with international quality standards and undergo rigorous testing procedures. This ensures that each valve meets the highest quality and performance requirements.

Technical Support: We provide comprehensive technical support to our customers. Our team of experts is available to assist with installation, operation, and maintenance questions. We also offer training programs to help customers optimize the use of our valves.

Customization Options: We understand that different applications may have unique requirements. Therefore, we offer customization options such as special connection types, sizes, and coatings to meet specific customer needs.

Designed for general industrial use, this floating ball valve combines WCB carbon steel’s structural strength with a modular two - piece body. The flanged connections simplify installation in high - flow systems, while the floating ball design provides dynamic sealing under pressure. Suitable for non - corrosive media, it offers zero leakage and low - torque operation in pipelines requiring frequent switching.

Product Name | Control Gas Carbon Steel WCB 6'' 300LB 2PC Flanged Floating Ball Valve |

Material | Stainless Steel/Duplex steel/Aluminium Bronze/Nickel-aluminum Bronze/Titanium Alloy, etc. |

Pressure | 150LB~2500LB |

Size | 1/2 inch~ 24 inch(DN15~DN600) |

End Connection | RF/RTJ/BW/SW |

Working Temp | -196ºC~400ºC option. |

Mode of operation | Hand wheel, Worm wheel, Pneumatic actuator & Electric Actuator. |

Suitable Medium | Water,Natural Gas,Oil and some corrosive liquid |

Features | Anti-blow out stem, Anti-statstic, Fire safe |

Modular Two - Piece Design for Easy Maintenance

The split - body construction allows field replacement of the ball, seats, or stem in ≤45 minutes without pipeline disassembly. This reduces maintenance downtime by 60% in power plants and water treatment facilities, where system shutdowns cost $150,000/hour. The design also enables quick cleaning of internal components in food & beverage processing.

Dynamic Sealing Under Pressure

A floating ball with self - adjusting PTFE seats compensates for pressure fluctuations, ensuring bidirectional bubble - tight sealing (ISO 5208 Class A). This is critical for oil refineries and gas distribution networks, where pressure surges can damage conventional valves. CFD analysis confirms consistent sealing even at 1.5x rated pressure, preventing product loss.

High - Temperature Performance

WCB carbon steel (ASTM A216) withstands temperatures up to 425°C, outperforming standard cast iron by 35%. This makes it suitable for steam lines in power plants, hot water systems in district heating, and asphalt production units. Independent tests show no creep deformation after 10,000 hours at 400°C.

Fire - Safe Compliance & Antistatic Features

Meets API 607 fire - safe standards with graphite packing and a stainless steel antistatic device. The latter prevents electrostatic buildup in flammable media like propane and ethylene, reducing ignition risks in storage terminals. Tests confirm zero leakage after 10 minutes of flame exposure, ensuring compliance with OSHA and EPA regulations.

Low - Torque Operation

A bevel gear mechanism reduces operating torque by 30% compared to manual valves, enabling single - operator operation even in 6" sizes. This is crucial for offshore platforms and remote pipelines, where accessibility is limited. The design also minimizes wear on internal components, extending service life to 15+ years.

Corrosion - Resistant Coatings

Optional fusion - bonded epoxy (FBE) coating (ISO 12944 - 5 C5 - M) provides 300% longer service life in aggressive environments compared to standard painting. Case studies show this coating prevents chloride - induced pitting in coastal power plants and sulfuric acid corrosion in fertilizer production.

Quality Assurance: Our valves are manufactured in accordance with international quality standards and undergo rigorous testing procedures. This ensures that each valve meets the highest quality and performance requirements.

Technical Support: We provide comprehensive technical support to our customers. Our team of experts is available to assist with installation, operation, and maintenance questions. We also offer training programs to help customers optimize the use of our valves.

Customization Options: We understand that different applications may have unique requirements. Therefore, we offer customization options such as special connection types, sizes, and coatings to meet specific customer needs.

In modern industrial fluid control systems, material selection often determines the service life and safety of the system. The ASTM B62 Bronze Gate Valve has become a core component in marine engineering, heating, ventilation, and air conditioning (HVAC) as well as water supply and drainage systems,

In the realm of industrial fluid handling, stainless steel Y-type strainers stand as a cornerstone of system reliability, efficiency, and longevity. Engineered to remove debris, particles, and contaminants from pipelines, these devices play a pivotal role in safeguarding equipment, reducing downtime

Structure and Working Principle of Double Disc Bronze Check ValveThe double disc bronze check valve is mainly composed of a valve body, two half-disc valve discs, a hinge mechanism, and sealing surfaces. The discs are connected by hinges and installed inside the valve body, enabling them to automati

In industrial fluid systems, filters are critical components that ensure system cleanliness and prevent contaminants from entering. The J-VALVES 2" 600LB CF8M Y-Type Filter is a high-efficiency, reliable filtration solution suitable for a wide range of industrial applications.1. High Pressure Resist

In industrial production, high temperature working conditions impose extremely stringent requirements on the performance of equipment. Especially in the filtration process involving high-temperature fluids, it is crucial to choose the appropriate filter material and model. Y-type strainer made of nickel aluminum bronze B148 (C95800) material have become the first choice for many engineers due to their excellent high temperature resistance and corrosion resistance.

What is a B62 Bronze Gate Valve?The B62 Bronze Gate Valve is a type of gate valve designed for industrial use, primarily in fluid control systems. Constructed from Ni-Al bronze, it offers excellent resistance to corrosion, high temperature, and pressure, making it an ideal choice for demanding envir

In the field of shipbuilding, seawater filtration is an important link to ensure the normal operation of key systems of ships. As a high-performance seawater filtration device, the C95800 strainer has become an indispensable component in shipbuilding due to its outstanding corrosion resistance, high

What Are Gate Valves?A gate valve is a type of valve that uses a sliding gate to control the flow of fluid. The gate moves vertically within the valve body to open or close the passage. When fully open, the gate valve creates a straight path for the flow of fluids, allowing minimal pressure drop. Ga

In modern industrial fluid control systems, tiny impurities are often the "invisible killers" that cause costly equipment failures. Founded in 2009, J-VALVES has been committed to the R&D and manufacturing of industrial valve solutions. Among our products, the Y-Strainer has become a core component for protecting pumps, compressors, and instrumentation systems due to its exceptional filtration efficiency and durability.

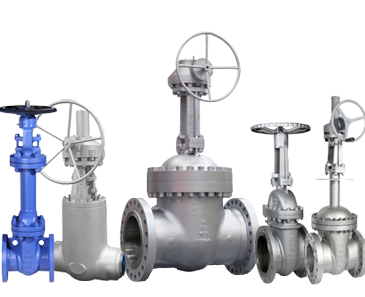

Understanding J-VALVES High-Performance Gate ValvesJ-VALVES' high-performance gate valves are designed with advanced engineering principles to ensure they can withstand the rigors of industrial use. These valves are available in a variety of sizes, materials, and configurations, allowing them to be

Selection Guide(1) Selection Based on Fluid CharacteristicsLiquid: If the fluid is water or a low-viscosity liquid with few impurities, a Y-type strainer can be selected; if the fluid is oil or contains a large amount of impurities, it is recommended to choose a basket strainer.Gas: For gas filtrati

In process systems such as petrochemical, industrial water treatment, energy, power, and fine chemical industries, pipeline clogging due to impurities remains one of the core issues affecting stable system operation. Once welding slag, rust, sand particles, or solid debris enter the pipeline, they not only cause valve jamming and pump wear but may also lead to unplanned shutdowns, resulting in high maintenance costs.

In the world of industrial processing, pipeline integrity is paramount. Any contamination within pipelines can result in costly damage to machinery, reduced efficiency, and potential downtime. This is where Basket and Y-type strainers come into play, serving as critical filtration devices for a vari

Y-type strainerStructural DesignThe Y-type strainer is shaped like the letter "Y". It is mainly composed of nozzles, the main pipe, a strainer screen, flanges and fasteners. The strainer screen is installed inside the main pipe. After the fluid enters from the inlet, it is strainered through the str

In industrial pipeline systems, protecting critical equipment from solid contaminants is essential for long-term reliability and operational safety. This is where the J-VALVES basket strainer plays a vital role. Designed for high flow capacity and efficient particle removal, it is widely used across industries where fluid cleanliness directly impacts system performance.

Understanding Double Block-and-Bleed (DBB) Ball ValvesDBB ball valves are designed to provide two independent seals (one upstream and one downstream) and a bleed port to vent any trapped fluid between the seals. This design ensures that the valve can safely isolate a section of the pipeline and reli

I. Application of Y-Type Filters in Fine Chemicals(1) Structural and Performance Characteristics Y-type filters are named for their shape resembling the letter "Y". They are mainly composed of connecting pipes, main pipes, filter screens, flanges and fasteners. Its filter screen is usually made of s

To our valued clients:On this cozy Christmas season, the J-VALVES team sends you warmest wishes—may your holidays be filled with joyful laughter, your ongoing projects run smoothly with efficiency, and the coming year bring more fruitful & win-win collaborations between us.J-VALVES specializes in pr

In industrial fluid systems, strainers are often not the most eye-catching equipment, but they are critical components that determine system stability and equipment lifespan. As can be seen from the images, J-VALVES Basket / Y-Type Strainers feature a striking red heavy-duty valve body design with a compact structure and clearly visible filtration elements, fully embodying their reliable positioning in industrial-grade applications.

Why Do Many Industrial Systems Still Suffer From Unexpected Pressure Drop and Blockage?<br /> <br /> In many industrial piping systems, Y strainers are considered “basic components” — simple, reliable, and easy to install. However, in real-world operation, engineers and maintenance teams often encounter recurring issues that lead to pressure loss, frequent shutdowns, and even downstream equipment damage.