| Availability: | |

|---|---|

| Quantity: | |

J-VALVES-GV-1551

J-VALVES

8481804090

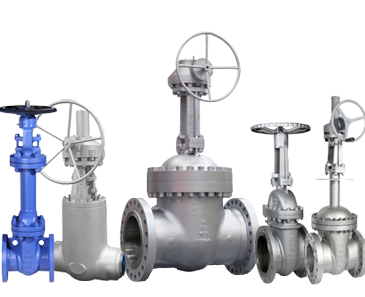

Product Name | 300LB RF Cast Cabon Steel WCB Gearbox Operation Rising Stem Gate Valve |

Material | WCB/CF8/CF8M/LCC/LCB/WC6/WC9 |

Pressure | 150LB/300LB/600LB/900LB/1500LB/2500LB |

Size | 2 inch~ 60 inch(DN50~DN1500) |

End Connection | RF/RTJ/BW/SW |

Working Temp | -196ºC~400ºC. |

Mode of operation | Handwheel (2"~12") & Bevel Gear (14"&above) |

Suitable Medium | Water,Natural Gas,Oil and some corrosive liquid |

Features | Rising stem,OS&Y,Bolted Bonnet or Pressure Sealed,non-rising stem option |

Customization Options:We offer a range of customization options for this gate valve. From different internal coatings to match specific fluid - handling requirements to tailored gear ratios for unique operational needs, purchasers can have the valve designed to fit their exact application, enhancing its functionality and compatibility.

Fire - Resistant Design:Designed with fire - resistant features, this valve can maintain its integrity during fire emergencies. Special materials and construction techniques are employed to prevent the valve from melting or deforming under high temperatures, ensuring the safety of the entire pipeline system in case of fire.

Anti - Static Properties:To prevent the build - up of static electricity, which can be a hazard in industries dealing with flammable fluids, this valve is equipped with anti - static components. This feature minimizes the risk of sparks that could potentially ignite the surrounding environment, adding an extra layer of safety.

Low - Maintenance Design:The valve's design focuses on minimizing maintenance efforts. Its robust construction and high - quality materials reduce wear and tear, and the accessible internal components make it easy to inspect and service. This means less downtime and lower maintenance costs for the end - user.

High - Precision Machining:Every component of this valve undergoes high - precision machining. This ensures tight tolerances between parts, resulting in a smooth - operating valve with excellent sealing performance. The precise machining also contributes to the valve's long - term reliability.

Noise and Vibration Reduction:Special engineering solutions are implemented to reduce noise and vibration during operation. This not only improves the working environment but also indicates the valve's stable performance. In industrial settings, excessive noise and vibration can be signs of potential mechanical problems, and this valve mitigates those concerns.

Installation: The valve is designed for easy installation. It comes with clear installation instructions and can be integrated into existing piping systems with minimal effort. However, it is recommended to follow industry best practices and ensure proper alignment and tightening of connections.

Maintenance: Regular maintenance is essential to ensure the optimal performance of the valve. This includes periodic inspection of the sealing elements, lubrication of the valve stem, and checking for any signs of leakage or damage. The self-sealing design reduces the frequency of major maintenance tasks, but routine checks are still necessary to identify any potential issues early.

Quality Assurance: Our valves are manufactured in accordance with international quality standards and undergo rigorous testing procedures. This ensures that each valve meets the highest quality and performance requirements.

Technical Support: We provide comprehensive technical support to our customers. Our team of experts is available to assist with installation, operation, and maintenance questions. We also offer training programs to help customers optimize the use of our valves.

Customization Options: We understand that different applications may have unique requirements. Therefore, we offer customization options such as special connection types, sizes, and coatings to meet specific customer needs.

Product Name | 300LB RF Cast Cabon Steel WCB Gearbox Operation Rising Stem Gate Valve |

Material | WCB/CF8/CF8M/LCC/LCB/WC6/WC9 |

Pressure | 150LB/300LB/600LB/900LB/1500LB/2500LB |

Size | 2 inch~ 60 inch(DN50~DN1500) |

End Connection | RF/RTJ/BW/SW |

Working Temp | -196ºC~400ºC. |

Mode of operation | Handwheel (2"~12") & Bevel Gear (14"&above) |

Suitable Medium | Water,Natural Gas,Oil and some corrosive liquid |

Features | Rising stem,OS&Y,Bolted Bonnet or Pressure Sealed,non-rising stem option |

Customization Options:We offer a range of customization options for this gate valve. From different internal coatings to match specific fluid - handling requirements to tailored gear ratios for unique operational needs, purchasers can have the valve designed to fit their exact application, enhancing its functionality and compatibility.

Fire - Resistant Design:Designed with fire - resistant features, this valve can maintain its integrity during fire emergencies. Special materials and construction techniques are employed to prevent the valve from melting or deforming under high temperatures, ensuring the safety of the entire pipeline system in case of fire.

Anti - Static Properties:To prevent the build - up of static electricity, which can be a hazard in industries dealing with flammable fluids, this valve is equipped with anti - static components. This feature minimizes the risk of sparks that could potentially ignite the surrounding environment, adding an extra layer of safety.

Low - Maintenance Design:The valve's design focuses on minimizing maintenance efforts. Its robust construction and high - quality materials reduce wear and tear, and the accessible internal components make it easy to inspect and service. This means less downtime and lower maintenance costs for the end - user.

High - Precision Machining:Every component of this valve undergoes high - precision machining. This ensures tight tolerances between parts, resulting in a smooth - operating valve with excellent sealing performance. The precise machining also contributes to the valve's long - term reliability.

Noise and Vibration Reduction:Special engineering solutions are implemented to reduce noise and vibration during operation. This not only improves the working environment but also indicates the valve's stable performance. In industrial settings, excessive noise and vibration can be signs of potential mechanical problems, and this valve mitigates those concerns.

Installation: The valve is designed for easy installation. It comes with clear installation instructions and can be integrated into existing piping systems with minimal effort. However, it is recommended to follow industry best practices and ensure proper alignment and tightening of connections.

Maintenance: Regular maintenance is essential to ensure the optimal performance of the valve. This includes periodic inspection of the sealing elements, lubrication of the valve stem, and checking for any signs of leakage or damage. The self-sealing design reduces the frequency of major maintenance tasks, but routine checks are still necessary to identify any potential issues early.

Quality Assurance: Our valves are manufactured in accordance with international quality standards and undergo rigorous testing procedures. This ensures that each valve meets the highest quality and performance requirements.

Technical Support: We provide comprehensive technical support to our customers. Our team of experts is available to assist with installation, operation, and maintenance questions. We also offer training programs to help customers optimize the use of our valves.

Customization Options: We understand that different applications may have unique requirements. Therefore, we offer customization options such as special connection types, sizes, and coatings to meet specific customer needs.

I. Key Factors of Sealing Performance(I) Sealing MaterialsThe sealing performance of trunnion ball valveslargely depends on the selection of sealing materials. Common sealing materials include polytetrafluoroethylene (PTFE), polyetheretherketone (PEEK), and metal seals. These materials not only have

I. Comparison of Structural Characteristics(I) Wedge Gate ValveThe gate of a wedge gate valve is wedge-shaped, and its sealing surface forms a certain angle with the vertical centerline (usually 2°52', 3°30', 5°, 10°, etc.). This design enables the gate to wedge into the valve seat when closed, form

Sealing Comparison(I) Sealing Performance of fully welded Ball ValvesThe sealing performance of fully welded ball valves is one of their most significant advantages. The valve body adopts an integral welding structure, eliminating potential leakage points at traditional flange joints. This design en

I. Structural Features of Trunnion Ball ValveThe core component of the trunnion ball valve is the ball, which is fixed to the valve body through trunnions. This structural design makes the ball more stable during rotation, reducing the risk of displacement caused by vibration or impact. Compared wit

Application scenarios in petroleum refiningThe petroleum refining process involves high temperatures, high pressures and corrosive media, which places extremely high demands on the performance of valves. The DBB ball valve is suitable for a variety of media, including aviation kerosene, light oil, n

In the field of industrial valves, J-VALVES, with its exquisite craftsmanship and excellent quality, has created a series of highly praised floating ball valves made in China. Whether it is a cast floating ball valve, a forged floating ball valve, a floating three-way ball valve, a flange floating b

Pneumatic ball valve is essentially the ball valve and the pneumatic actuator clever combination. Its working principle is based on the precise control of the air source by the pneumatic actuator. When the air source enters or exits the pneumatic actuator according to the command, the powerful drivi

Top entry trunnion mounted ball valve is mainly composed of valve body, valve seat, ball, valve stem, packing box and operating mechanism and other components. Its core components are ball and valve seat. The ball is connected with the operating mechanism through the valve stem to realize 90-degree

I. Working Principle of Gate ValveThe gate valve consists of a valve body, a gate, a valve stem, a valve seat, and a driving device. When opening, the driving device drives the gate to move upward through the valve stem, opening the medium passage. When fully open, the flow resistance is close to th

In the highly competitive industrial field, efficiency is of vital importance. And the 3" 300LB flange floating ball valve manufactured by J-VALVES in China is undoubtedly the accelerating engine that helps boost industrial efficiency.

At present, when environmental protection has become a global mission, every detail in the industrial field is related to the green future. The J-VALVES butt-welding floating ball valve, with its unique advantages, is taking on the important role of an eco-friendly valve. Its sealing performance is

Applications in the Upgrading and Reconstruction of Urban Pipe Networks(I) Urban Gas SystemIn the urban gas pipeline network, fully welded ball valves are used to control and cut off the flow of gas. Their zero-leakage performance and corrosion resistance ensure the safety of gas transportation and

Unique low-temperature design. Low-temperature flange gate valves are specially designed for low-temperature environments and can withstand operation under extreme low-temperature conditions. Their key components are made of special low-temperature materials such as low-temperature steel or stainles

As a high-performance industrial valve, trunnion ball valves are widely used in high-pressure and high-temperature working conditions in industries such as petroleum, natural gas, and chemical engineering. However, due to the complexity of its working environment, the stability of trunnion ball valv

In the field of industrial valves, the ASME B16.34 standard is one of the most authoritative and widely recognized design and manufacturing specifications globally. This standard covers valves with flange, threaded, and welded end connections, providing comprehensive guidance for the design, manufac

Design features of bolted bonnet connecting gate valve(I) Structural compositionThe bolted bonnet connection gate valve is mainly composed of parts such as the valve body, bonnet, gate plate, valve stem, bolts and seals. The valve body and bonnet are connected by bolts to form a sealed integral stru

Application of Pressure Seal Gate Valves in Oil and Gas Pipelines(I) High-pressure Transmission PipelinesThe long-distance transportation of oil and natural gas usually requires a high-pressure pipeline system. The pressure-seal gate valve can withstand a pressure rating of up to Class 2500, and is

Application fields of flange gate valves(I) Oil and Gas IndustryIn oil and gas transmission pipelines, flanged gate valves are used to control the flow and cut off of the medium. Their high-strength structure and reliable sealing performance enable them to withstand high pressure and high-temperatur

working principleBall ValveThe core component of a ball valve is a sphere with a central hole. The fluid is cut off and opened by rotating the sphere 90 degrees. The sphere is installed in the valve body and closely cooperates with the valve seat to form a seal. When the hole of the sphere is aligne

In the oil and gas industry, valves, as key fluid control equipment, have a direct relationship between their performance and reliability and the safety and efficiency of the entire production system. As a high-performance valve type, high-pressure large-diameter trunnion ball valves, with their uni