Views: 0 Author: Site Editor Publish Time: 2024-04-10 Origin: Site

When pondering over the intricacies of fluid systems, whether in industrial settings, residential plumbing, or specialized applications like aquariums or pools, the question of whether a check valve is necessary often surfaces. Understanding the role and importance of a check valve can significantly impact the efficiency, safety, and maintenance of your system.

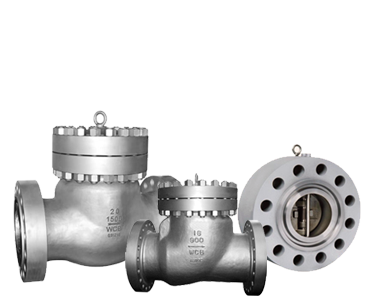

A check valve, a crucial component in many fluid systems, serves a fundamental purpose: to allow fluid (liquid or gas) to flow in one direction while preventing backflow. This seemingly simple function is vital for preventing potential damage or malfunction within systems. Let's delve deeper into the mechanics and benefits of incorporating a check valve into your setup.

The design of a check valve is ingeniously simple. It operates based on pressure differential; when the pressure on the upstream side exceeds that on the downstream side, the valve opens, allowing flow. Conversely, if backflow occurs, the differential pressure decreases, prompting the valve to close. This automatic functionality makes check valves an indispensable asset in preventing reverse flow without manual intervention.

Incorporating a check valve into your system offers numerous advantages. Primarily, it protects against backflow, which can cause contamination, damage to equipment, and disruptions in process flow. Additionally, check valves are crucial for maintaining pressure and preventing water hammer – a sudden surge in pressure that can lead to significant damage.

The versatility of check valves is evident in their wide range of applications. From domestic water systems and sewage treatment plants to chemical processing and pharmaceutical industries, the need for reliable one-way flow is universal.

In residential settings, a check valve is often installed in sump pumps to prevent flooded basements by ensuring that water flows only outwards. Similarly, they are used in water heaters to prevent contaminated water from flowing back into the clean water supply.

In more complex industrial contexts, check valves play critical roles in process control, ensuring that gases and liquids move in the correct direction to maintain safety and efficiency. Their importance cannot be overstated in systems where chemical compatibility and pressure differentials are critical considerations.

Selecting the appropriate check valve for your application requires careful consideration of several factors, including the type of fluid, pressure and temperature conditions, and installation requirements. Different types of check valves, such as swing, lift, and ball check valves, offer varying benefits depending on these conditions.

The construction material of a check valve plays a significant role in its compatibility with different fluids and its overall durability. Common materials include stainless steel, brass, and PVC, each offering different levels of resistance to corrosion, temperature, and pressure.

Proper installation and regular maintenance are essential for the optimal performance of a check valve. Incorrect installation can lead to malfunction, reduced efficiency, and even failure. Regular checks ensure that valves remain free from debris and operational issues that could impede their function.

In conclusion, the necessity of a check valve largely depends on the specific requirements and characteristics of your fluid system. For most applications involving liquid or gas flow in one direction, the answer is unequivocally yes. A check valve not only enhances safety and efficiency but also protects against potential damage caused by backflow. By carefully selecting the right type and material for your application and adhering to proper installation and maintenance practices, you can ensure that your system operates smoothly and reliably.

In essence, while the humble check valve may seem like a minor component in the grand scheme of fluid systems, its role is anything but insignificant. It is a testament to the idea that sometimes, it's the small details that make all the difference in achieving optimal performance and protection in any system.